The oil seals on my John Deere 855 (compact tractor) hydraulic steering cylinder (AM108897 or AM105772) are fine but the ball joints are 'shot'. Is there a way of grinding off the existing ball joints and welding on new ones? If this is possible does anyone know which replacement ball joints would fit. Any help/advice welcome.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JD 855 hydraulic steering cylinder

- Thread starter Nick S

- Start date

/ JD 855 hydraulic steering cylinder

#1

CADplans

Elite Member

Nick S,, are yours falling apart, or just "sloppy" ?

I doubt I would do anything until they fall apart,,

We have a JD 855,, with a loader, we are not having any issue ,, so far,,

I doubt I would do anything until they fall apart,,

We have a JD 855,, with a loader, we are not having any issue ,, so far,,

Tinhack

Elite Member

- Joined

- Jul 3, 2020

- Messages

- 2,500

- Location

- Lytle, TX

- Tractor

- Ford 3910, John Deere 420C, Kubota G32XKS, IH 2606, Bad Boy Maverick-60"

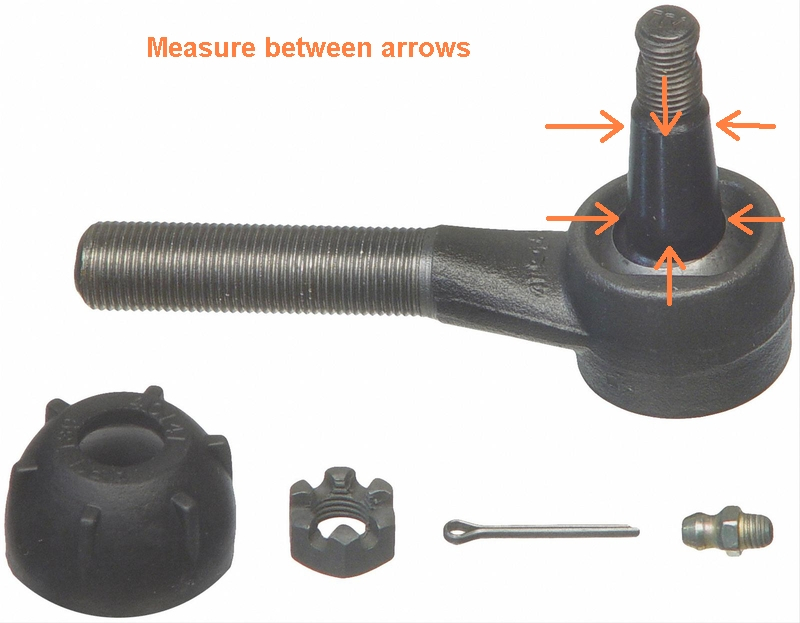

I'd be looking at "tie rod ends" rather than "ball joints". The two terms mean different parts on this side of the pond. Take yours apart and measure the two ends of the taper. Many rod ends will have a common taper but the size will vary based on vehicle weight factors. (Strength needed at the union)

Take your measurements to an auto supply store and check a few tie ends.

Take your measurements to an auto supply store and check a few tie ends.

Thanks for the feedback. I naturally assume that once I have found a suitable tie rod end then I need to cut the old one off and weld on the new one. I have a concern about protecting both the cylinder seals and the new tie rod end from the heat during welding but will try to introduce a heat sink to protect from this.

Tinhack

Elite Member

- Joined

- Jul 3, 2020

- Messages

- 2,500

- Location

- Lytle, TX

- Tractor

- Ford 3910, John Deere 420C, Kubota G32XKS, IH 2606, Bad Boy Maverick-60"

Work the rod in and out of the cylinder to expel as much hydraulic fluid as possible. The rubber parts of the cylinder will be on the piston and at the rod opening to the cylinder. Extend the rod all the way out and wrap wet rags around the rod near the tie rod end and cylinder near the far end fluid coupling. Do not cover the fluid openings.

You should be able to weld the new end(s) without creating too much heat but don't dilly-dally with the sparker.

You should be able to weld the new end(s) without creating too much heat but don't dilly-dally with the sparker.

Tinhack

Elite Member

- Joined

- Jul 3, 2020

- Messages

- 2,500

- Location

- Lytle, TX

- Tractor

- Ford 3910, John Deere 420C, Kubota G32XKS, IH 2606, Bad Boy Maverick-60"

Forgot to mention; Tie Rod Ends are typically forged steel so don't quench them or you could lock the ball inside by shrinkage. Grease will most likely melt out so get ends with a Zerk fitting so they can be greased. Good luck and keep us posted.

TractorGuy

Elite Member

- Joined

- Sep 15, 2013

- Messages

- 4,611

- Location

- N. FL

- Tractor

- John Deere 4310 CUT, Ford New Holland 575E Industrial Backhoe, John Deere F725 Front Mount Mower

I would try finding a rod end type cylinder to replace it with. You could drill out the female tapers or just use a bolt that will pass through the small end.

Something like this as an example. (I don't know your dimensions)

Something like this as an example. (I don't know your dimensions)

Double Acting Hydraulic Cylinders | Hydraulic Cylinders | Hydraulics | www.surpluscenter.com

Double Acting Hydraulic Cylinders,Hydraulic Cylinders,Hydraulics, 4" x 8" x 2" DA HYD CYL Brand new, PRINCE. Double

www.surpluscenter.com

Last edited:

CADplans

Elite Member

Extend the cylinder fully in the direction of the rod being welded, the seal will never even get warm, let alone get damaged.I have a concern about protecting both the cylinder seals and the new tie rod end from the heat during welding but will try to introduce a heat sink to protect from this.

Nothing on the planet can absorb as much heat per unit of weight compared to water.

The perfect way to protect the rod during welding is to wrap the rod with a wet rag,, the heat will not get past the edge of the rag far enough to do damage.

Have a water bottle ready, and re-wet the rag as soon as the welding is complete.

I stick weld assemblies like this, so the welding is complete in only a dozen or so seconds, or less.

Keep rewetting the rag, until the rod is cool to the touch.