Hello all,

I have been having hydraulic issues with my 830 JD 3 point lifting power this spring.

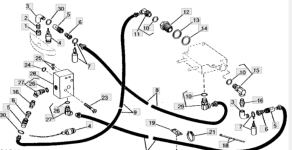

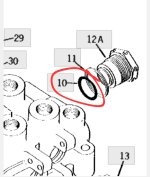

How it started was I dropped the 3 point arms with a box blade too hard last year and it ended up breaking the cam follower tip that links to the rockshaft linkage inside the top cylinder housing. This caused the 3 point to raise to full up until I set the LD to L and I could run like this for a while, till this year.

I bought a new cam follower and installed it thinking this would cure my entire problem. It did kind of. I can control the arms perfectly up and down without the box blade on. Up and down and the different LD settings all respond really well. But when I attach a heavy implement it can't lift them off the ground or just barely. I have a front end loader and it works fine on the same pressure line as the RS.

What I have checked on the hydraulics is. New oil, Filter, screen, checked the filter bypass valve, dump valve, pressure relief, rate of drop adjustment under the seat. All the linkages and springs in the RS housing when removed look great. I have adjusted the cam follower to the JD tech manual and also the RS neutral positions. Nothing seems to increase lifting power. The large cam follower arm and associated load control shaft connection to it.

Things I have not checked. Transmission pressure relief, RS actual guaged pressure, the thermal relief valve on the lift cylinder housing, or the RS lift cylinder and piston seal itself.

I am going to use a scope to watch the lift cylinder rod side for possible blow by today through the fill cap. And I'm also going to check the RS hydraulic pressure with a guage on the test port asap.

When I tilt the loader bucket back to just dead head it, the main pressure relief opens as it should and as soon as I let off quickly with my 3 point lift lever already in the full up position, it will start to lift a heavy implement about an inch each time and hold it in relief and let off quick. Probably due to shocking the hydraulic line pressure a smidge during let off? When I finally get a heavy implement up off the ground decent, it will hold it all day long.

I am thinking at this point should I rebuild the RS cylinder and or replace the thermal relief if I find out the pressure check to the RS test port not to be acceptable?

Any advise would be greatly appreciated.

Thanks in advance,

Mike

I have been having hydraulic issues with my 830 JD 3 point lifting power this spring.

How it started was I dropped the 3 point arms with a box blade too hard last year and it ended up breaking the cam follower tip that links to the rockshaft linkage inside the top cylinder housing. This caused the 3 point to raise to full up until I set the LD to L and I could run like this for a while, till this year.

I bought a new cam follower and installed it thinking this would cure my entire problem. It did kind of. I can control the arms perfectly up and down without the box blade on. Up and down and the different LD settings all respond really well. But when I attach a heavy implement it can't lift them off the ground or just barely. I have a front end loader and it works fine on the same pressure line as the RS.

What I have checked on the hydraulics is. New oil, Filter, screen, checked the filter bypass valve, dump valve, pressure relief, rate of drop adjustment under the seat. All the linkages and springs in the RS housing when removed look great. I have adjusted the cam follower to the JD tech manual and also the RS neutral positions. Nothing seems to increase lifting power. The large cam follower arm and associated load control shaft connection to it.

Things I have not checked. Transmission pressure relief, RS actual guaged pressure, the thermal relief valve on the lift cylinder housing, or the RS lift cylinder and piston seal itself.

I am going to use a scope to watch the lift cylinder rod side for possible blow by today through the fill cap. And I'm also going to check the RS hydraulic pressure with a guage on the test port asap.

When I tilt the loader bucket back to just dead head it, the main pressure relief opens as it should and as soon as I let off quickly with my 3 point lift lever already in the full up position, it will start to lift a heavy implement about an inch each time and hold it in relief and let off quick. Probably due to shocking the hydraulic line pressure a smidge during let off? When I finally get a heavy implement up off the ground decent, it will hold it all day long.

I am thinking at this point should I rebuild the RS cylinder and or replace the thermal relief if I find out the pressure check to the RS test port not to be acceptable?

Any advise would be greatly appreciated.

Thanks in advance,

Mike