scott_vt

Super Member

- Joined

- Oct 5, 2004

- Messages

- 7,336

- Location

- east wells,vt

- Tractor

- 1986 MF 1040, 1942 Farmall A, 1949 Farmall Super A

Mornin Guys,

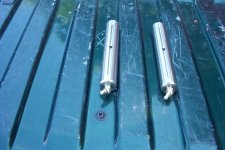

I thought I would post what I ended up doing to replace two of my loader pins. The pins were not getting any grease because one of the grease fittings had broke off on one side and on the other the threads were stripped out. Rather than going through welding and redrilling and tapping for new zerks I fabricated new 1" stainless pins. I drilled the pins from the end to the center and tapped the ends for the zerks. I drilled a connector hole in the middle of the pins and milled a grease groove along the length stopping before the ends. Im attaching pictures, to help explain what Im trying to say ! Hopefully someone else with an older tractor that has this problem could possibly use this idea !

Hopefully someone else with an older tractor that has this problem could possibly use this idea !

I thought I would post what I ended up doing to replace two of my loader pins. The pins were not getting any grease because one of the grease fittings had broke off on one side and on the other the threads were stripped out. Rather than going through welding and redrilling and tapping for new zerks I fabricated new 1" stainless pins. I drilled the pins from the end to the center and tapped the ends for the zerks. I drilled a connector hole in the middle of the pins and milled a grease groove along the length stopping before the ends. Im attaching pictures, to help explain what Im trying to say !