WoodChuckDad

Elite Member

- Joined

- Jul 15, 2015

- Messages

- 2,714

- Location

- Free Union, VA

- Tractor

- Kioti RX7320 Power Shuttle Cab, Komatsu PC130-6

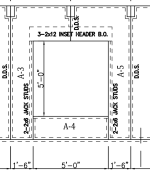

Thank you, everyone for the great ideas. Keep them coming, please. You may see me grabbing onto some of them in the videos. I am willing to try just about anything that will fit the specific situation. It's Christmas Morning. This afternoon, My wife wants to go out there and work on the header for the next window section we are putting in. It's a monster. Looking at the plans, it is two L-shaped pieces that come together at the top, with a header underneath and a bottom section below that. Those three pieces will be 8 feel long all together. The header is over 5 feet long and made from 3 2x12's. I can't think of a Way to put this together piece by piece so I think I am going to assemble the pieces upside down, then use the excavator to lift it up and set it into place. Then use some ratchet straps and a come along to work it into place.