Fallon

Super Member

I'm going to be running 3 conduits from the house out to the end of my driveway. 1 power (20@ circuit), 1 for fiber, & one because conduit is cheap & trenches are expensive. Total run is about 350'. I've got several 100' chunks & 50' chunks glued up already & laying next to the driveway. I've got a 3pt trencher for my tractor that cuts a 6" trench up to about 3' deep (not quite enough to clear the frost line here in Colorado).

I don't expect more than 3@ normal use tops, probably less, occasionally using 10-15@ a few times a year for HAM radio field day out in the pasture or an occasional power tool. Debating between 12 & 10 gauge, possibly 8 to fight voltage drop. Shouldn't be a big deal at the average amp or 2 of draw going into regulated 12v power supplies (for that matter most of my higher amp usages will be HAM radio field day, also into regulated 13.5v power supplies). But I'll figure that out at some point after the conduit is all installed.

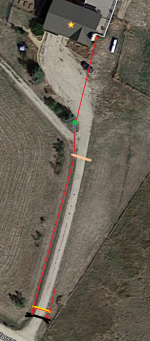

East side option: Pretty much a straight run for 350', except for the sweep 90's at each end.

West side option: Not quite as straight, but I have a spot for a pull box 100' from the house & would end up putting in a 30-40' chunk of drain pipe in the same trench in under a driveway to later pull some drip line in.

In either case I'm likely dropping in 2 30' conduits to go under the driveway right next to the arch & another down the side driveway on the outbound drivers side to put a button on a post for an eventual gate opener.

Where is a good cheap source for a pull box? Don't see any listed at Home Depot/Lowes & I assume the $30 plastic sprinkler ones aren't rated or appropriate for electrical.

Red = new conduit I need to put in

Blue = 3-4" conduit I'd put in if I went that way (would terminate next to the pull box, not in the pull box)

Green = pull box

Pink = existing 16" culvert

Yellow = 6" small culvert I'd likely put in

West side route East side route

East side route

Ranch arch at the end of the driveway

I don't expect more than 3@ normal use tops, probably less, occasionally using 10-15@ a few times a year for HAM radio field day out in the pasture or an occasional power tool. Debating between 12 & 10 gauge, possibly 8 to fight voltage drop. Shouldn't be a big deal at the average amp or 2 of draw going into regulated 12v power supplies (for that matter most of my higher amp usages will be HAM radio field day, also into regulated 13.5v power supplies). But I'll figure that out at some point after the conduit is all installed.

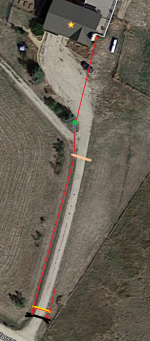

East side option: Pretty much a straight run for 350', except for the sweep 90's at each end.

West side option: Not quite as straight, but I have a spot for a pull box 100' from the house & would end up putting in a 30-40' chunk of drain pipe in the same trench in under a driveway to later pull some drip line in.

In either case I'm likely dropping in 2 30' conduits to go under the driveway right next to the arch & another down the side driveway on the outbound drivers side to put a button on a post for an eventual gate opener.

Where is a good cheap source for a pull box? Don't see any listed at Home Depot/Lowes & I assume the $30 plastic sprinkler ones aren't rated or appropriate for electrical.

Red = new conduit I need to put in

Blue = 3-4" conduit I'd put in if I went that way (would terminate next to the pull box, not in the pull box)

Green = pull box

Pink = existing 16" culvert

Yellow = 6" small culvert I'd likely put in

West side route

East side route

East side route

Ranch arch at the end of the driveway