SylvainG

Platinum Member

Hi, looking at different charts, welding 3/16" steel with a MIG and flux wire has a way higher amp requirement than 1/4" steel.

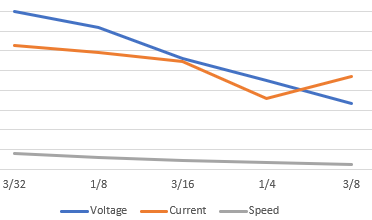

I thought maybe that calculator was wrong so I tried different sites and they all produce the same result. Speed seems to be linearly increasing, voltage is up but it's the same voltage for 1/4" steel, so why is the current requirement so high for 3/16"?

Here's one of them:

www.millerwelds.com

www.millerwelds.com

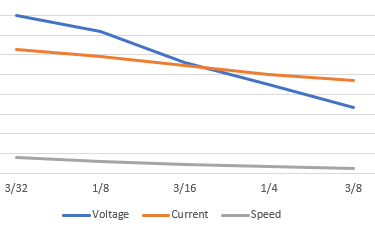

Edit: Actually, I think it's more like the 1/4" value that is 'wrong'. 250A seems to create a straight line when comparing current against thickness for all the thickness there. Is that it or is 1/4" 'special'?

With value above:

With 250A for 1/4

Edit 2: Sorry if you're on mobile (app). The table doesn't display properly there

| Thickness | 3/32" | 1/8" | 3/16" | 1/4" | 3/8" |

| Speed | 145-155 | 175-185 | 205-215 | 220-230 | 245-255 |

| Current | 110-125 | 140-155 | 190-220 | 170-190 | 330-375 |

| Voltage | 14-15 | 14-15 | 15-16 | 15-16 | 16-17 |

I thought maybe that calculator was wrong so I tried different sites and they all produce the same result. Speed seems to be linearly increasing, voltage is up but it's the same voltage for 1/4" steel, so why is the current requirement so high for 3/16"?

Here's one of them:

MIG Flux-Cored Weld Setting Calculator | MillerWelds

Browse suggested weld parameter settings forMIG (Flux-Core) Welding.

Edit: Actually, I think it's more like the 1/4" value that is 'wrong'. 250A seems to create a straight line when comparing current against thickness for all the thickness there. Is that it or is 1/4" 'special'?

With value above:

With 250A for 1/4

Edit 2: Sorry if you're on mobile (app). The table doesn't display properly there

Last edited: