This is an issue misalignment on both sides of the shaft(s).

Hole #1, lets say the PTO shaft - (Female) is aligned like this ---> |

Hole # 2, gear box shaft - (Male) is aligned like this ---> /

The PTO shaft spins and spins and spins and spins. I have rotated the PTO shaft AD NAUSEM and the holes are still misaligned. I've owned the rotary cutter for a total of 8 months and did not start mowing with it until this spring. It is not rusted. There is only a mild amount of surface rust - Florida is wet.

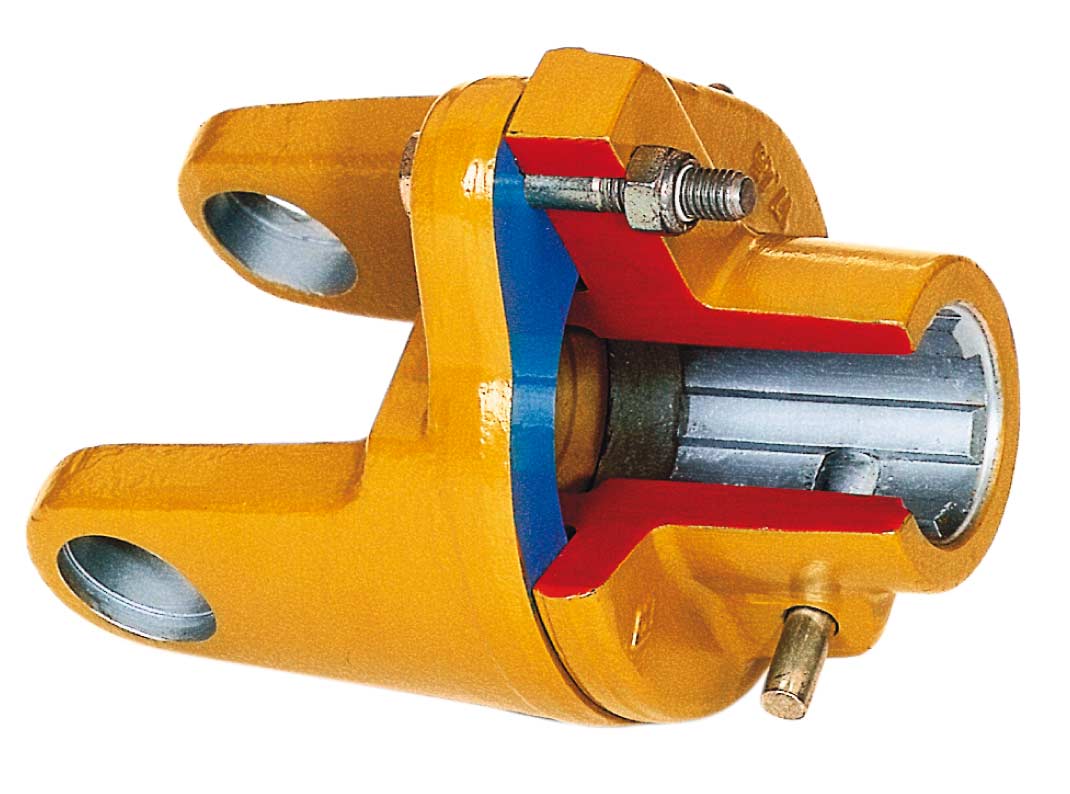

Talking with local dealer again today and sharing these photos he can confirm that the Grade 8 bolt 1/2" x 3 1/2" is correct. Ayup. He also said, after looking at the photos I sent him, "the machine has a slip clutch built into the drive shaft. Without being there to see why the holes are not lining up I would try to adjust the alignment or use a tapered pry bar".

Do I have a miracle rotary cutter that has both a Slip Clutch and a Shear bolt? Cause the specs on these things say Shear Bolt OR Slip Clutch. This is the repair guy.....

When I asked if I used a pry bar and eff it up more would that void my warranty, he said they can come get it for $100 and haul it to their shop.

Reposting 2 photos, now labled and images of the absolute worst pasture anyone has ever had to mow.... it's a wonder I don't roll my tractor or break a shear bolt every time I've mowed it.