Richard

Elite Member

- Joined

- Apr 6, 2000

- Messages

- 4,822

- Location

- Knoxville, TN

- Tractor

- International 1066 Full sized JCB Loader/Backhoe and a John Deere 430 to mow with

So I have an old 15 foot 'Terrain King' (now owned by Alamo) hydraulically powered flexwing mower. (a speed increaser attaches to PTO and hydraulic pump attaches to increaser then powers the blades)

Cut a field a week ago and noticed that one blade section cut like a ginsu knife.... the opposite wing cut like 50% and the center section was strange, it didn't cut much, just ripped up some of the taller stuff (think knee height).

So I presume the motors are at issue since if the primary pump didn't work, none of the blades would work. None the less, they might all need attention!!! So I'll start at one end and see what happens.

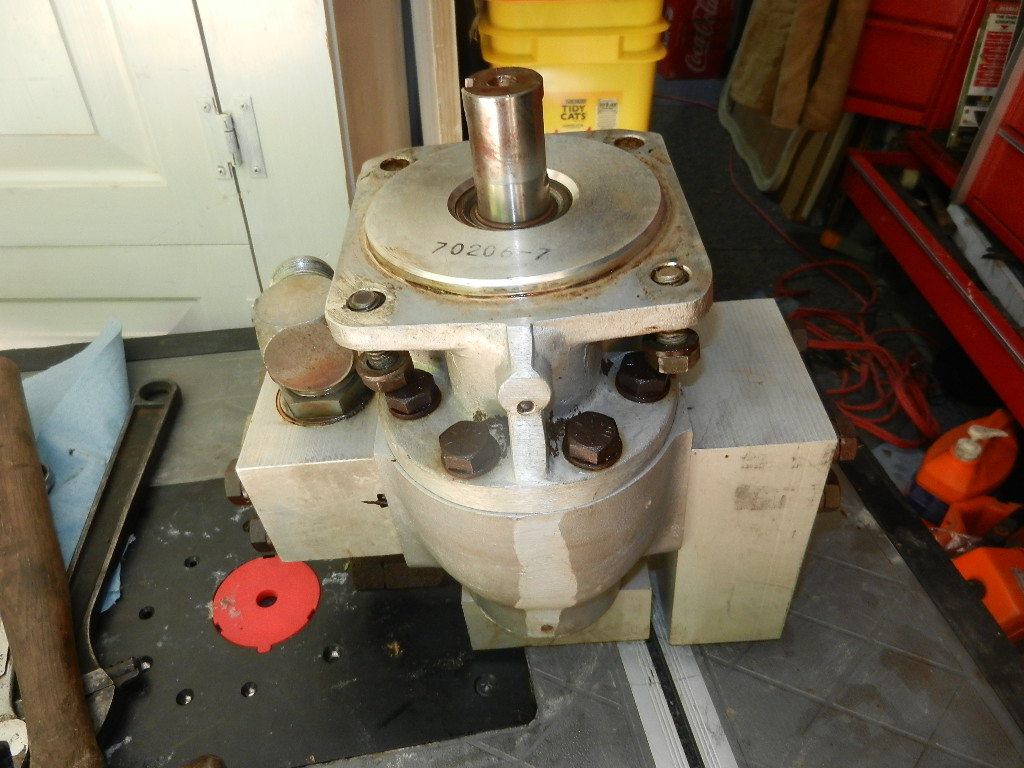

Here's the motor after having taken it off the housing (the lower part of the housing is what the blade carrier is attached to)

I have NEVER ever done anything like this but presume it can't be too complicated.... Note however, most of those bolts are UNDER the lip of the top section. Can't get to them with my impact. My crows foot is also useless.... this is going to be brute force with a box wrench (and these things are TIGHT AND old)

I don't know the names of the parts....but the two side "boxes" (fluid input and output) have to come off as well as the pressure relief (which is what it's currently sitting on.....on top/bottom) I took all the attached items off. The two side boxes had a single O-ring and the pressure relief box had three small ones, about the size of a dime. No picture of that one!

So my impact wrench was utterly useless on these bolts that connect the halves together. Crows foot also useless.... what to do? The instructions (yes I have a manual and actually read it!) calls for putting this in a vice. Guess what I don't have. So.... maybe I can get some leverage by holding it and using a longer "bar" (wood clamp) to hold it from twisting as I try to turn the bolts...... didn't work.

BUT ALAS.... I am a persistent little fool and willing to keep fighting the fight. Besides, I have a backhoe. What on earth you wonder, does a backhoe have to do with this? Well.....think of those threads where people ask about uses for a backhoe.....are they "REALLY" that useful???

HA! I laugh in thy face!!

Yet another useful use to add to the "why should I buy a backhoe" question.... I put some wood down, put some wood on top and clamped it. No, I didn't put the 16,000 pounds of weight on it (or whatever the machine weighs) BUT, I was able to hold the motor in place while I took my box wrench and pounded on the wrench with a 5 pound hammer and finally got the bolts loosened up. I then had to flip the motor over to get the other side.

Now, reading the instructions, they say "place thumbs on the shaft, grab the lips of the top half and gently pull straight up. If it's stuck, you can tap it with a wooden or rubber mallet. Well.... that was written for Shirley Temple.... this thing wasn't coming apart. Hit it with the rubber mallet....I DID finally see an edge of light but my poor little thumbs didn't have the strength to push it through.... so.... pulled out the puller and came off easy-peasy.

I might add... I'd noticed a leak on the underside of the mower, where the blades come through. This suggests to me that this motor is leaking which means I need bottom seals which is really why I'm doing this. So back to directions.... "gently tap on the lower gasket all the way around to tap it out from above" (OMG, who writes this kind of stuff..... yeah yeah.... I tapped it into gasket purgatory.

Might be worth knowing I'm taking the guts of this to the hydraulic shop and buying three sets of everything so I can do all three motors. Now the directions call for you to "go back to your vice" (uh oh....) and use the vice to press fit the new lower seals in. This might be an issue. This was VERY difficult to extract (both of them) and no, I won't smash it with the backhoe stabilizer.... I might take it to my machine shop friend but don't want to impose. I might buy an extra set of them and see if I can simply tap them in with the socket method. If I booger it up, I'll have a spare for a new plan "B"

Now....what I can't yet decide......do I take the impellers apart? As best I can tell from the instructions, there aren't any seals in that section. The instructions DO show how to take it apart.....but I'm thinking there's no need to if there are no seals in there....after all, why take it apart to just put it back together? If I'm wrong on this, I'm happy to hear input.

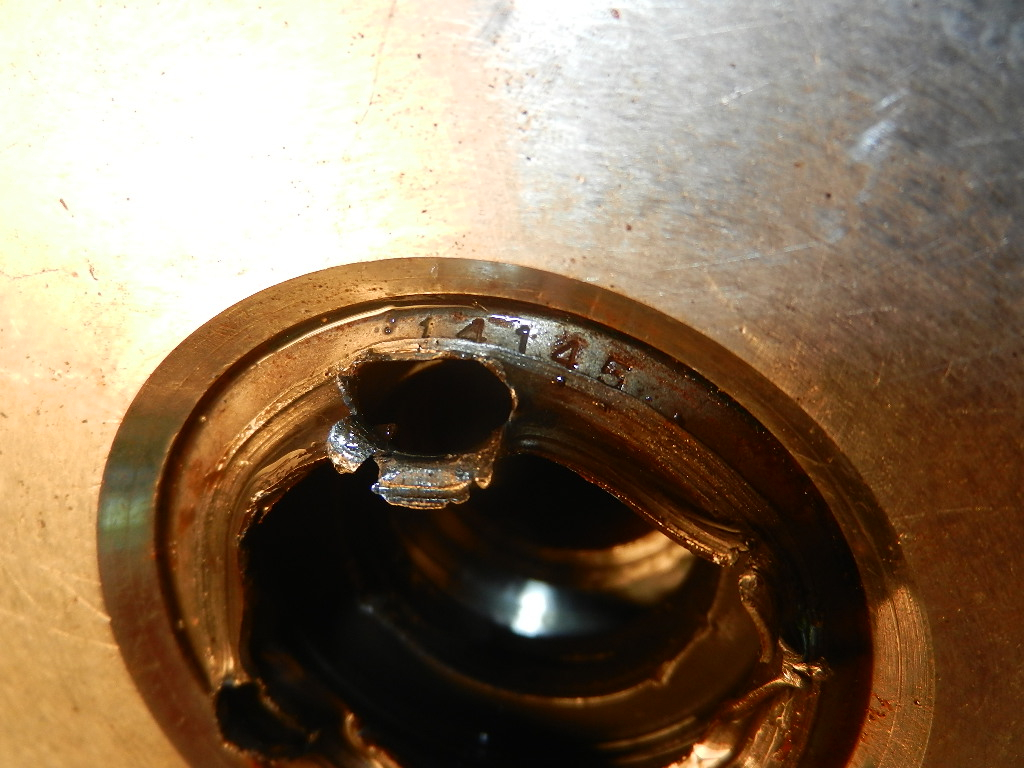

Here's what it looks like when split. I've already removed the O-ring.

Did this yesterday so don't have the replacement seals yet.

Cut a field a week ago and noticed that one blade section cut like a ginsu knife.... the opposite wing cut like 50% and the center section was strange, it didn't cut much, just ripped up some of the taller stuff (think knee height).

So I presume the motors are at issue since if the primary pump didn't work, none of the blades would work. None the less, they might all need attention!!! So I'll start at one end and see what happens.

Here's the motor after having taken it off the housing (the lower part of the housing is what the blade carrier is attached to)

I have NEVER ever done anything like this but presume it can't be too complicated.... Note however, most of those bolts are UNDER the lip of the top section. Can't get to them with my impact. My crows foot is also useless.... this is going to be brute force with a box wrench (and these things are TIGHT AND old)

I don't know the names of the parts....but the two side "boxes" (fluid input and output) have to come off as well as the pressure relief (which is what it's currently sitting on.....on top/bottom) I took all the attached items off. The two side boxes had a single O-ring and the pressure relief box had three small ones, about the size of a dime. No picture of that one!

So my impact wrench was utterly useless on these bolts that connect the halves together. Crows foot also useless.... what to do? The instructions (yes I have a manual and actually read it!) calls for putting this in a vice. Guess what I don't have. So.... maybe I can get some leverage by holding it and using a longer "bar" (wood clamp) to hold it from twisting as I try to turn the bolts...... didn't work.

BUT ALAS.... I am a persistent little fool and willing to keep fighting the fight. Besides, I have a backhoe. What on earth you wonder, does a backhoe have to do with this? Well.....think of those threads where people ask about uses for a backhoe.....are they "REALLY" that useful???

HA! I laugh in thy face!!

Yet another useful use to add to the "why should I buy a backhoe" question.... I put some wood down, put some wood on top and clamped it. No, I didn't put the 16,000 pounds of weight on it (or whatever the machine weighs) BUT, I was able to hold the motor in place while I took my box wrench and pounded on the wrench with a 5 pound hammer and finally got the bolts loosened up. I then had to flip the motor over to get the other side.

Now, reading the instructions, they say "place thumbs on the shaft, grab the lips of the top half and gently pull straight up. If it's stuck, you can tap it with a wooden or rubber mallet. Well.... that was written for Shirley Temple.... this thing wasn't coming apart. Hit it with the rubber mallet....I DID finally see an edge of light but my poor little thumbs didn't have the strength to push it through.... so.... pulled out the puller and came off easy-peasy.

I might add... I'd noticed a leak on the underside of the mower, where the blades come through. This suggests to me that this motor is leaking which means I need bottom seals which is really why I'm doing this. So back to directions.... "gently tap on the lower gasket all the way around to tap it out from above" (OMG, who writes this kind of stuff..... yeah yeah.... I tapped it into gasket purgatory.

Might be worth knowing I'm taking the guts of this to the hydraulic shop and buying three sets of everything so I can do all three motors. Now the directions call for you to "go back to your vice" (uh oh....) and use the vice to press fit the new lower seals in. This might be an issue. This was VERY difficult to extract (both of them) and no, I won't smash it with the backhoe stabilizer.... I might take it to my machine shop friend but don't want to impose. I might buy an extra set of them and see if I can simply tap them in with the socket method. If I booger it up, I'll have a spare for a new plan "B"

Now....what I can't yet decide......do I take the impellers apart? As best I can tell from the instructions, there aren't any seals in that section. The instructions DO show how to take it apart.....but I'm thinking there's no need to if there are no seals in there....after all, why take it apart to just put it back together? If I'm wrong on this, I'm happy to hear input.

Here's what it looks like when split. I've already removed the O-ring.

Did this yesterday so don't have the replacement seals yet.