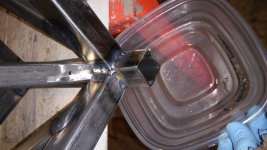

Not sure if this is contamination or what, but I've been welding this frame together with no problem on all the other joints. All of a sudden this one joint causes sparkling and popping, it contaminates the tungsten even though the tungsten doesn't touch. In the photo you can see it leaves a brown residue and a very pock marked looking attempt at a weld. What's causing this? This is the same material I used on the whole frame, it's 3/4" square steel tubing with .065 wall, same welder, same filler, same human doing the welding. Could this be oil or something that's inside this one piece of material?