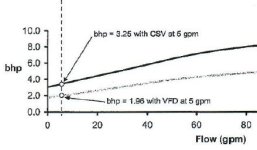

No, you have it. You are reading the chart right. About 43% less energy to run the VFD pump.

There are reasons why VFD are used so frequently in industrial use; energy and cost savings.

All the best,

Peter

A VFD can burn 43% less energy than a control valve at minimum speed. But 43% of 3.25HP doesn't add up to much. A VFD can burn 12.9% less energy from this 10HP pump than a control valve, which isn't much different either. A VFD burns 5% more energy than a control valve at full pump speed and flow. A 5% increase added to the 10HP load can add up quickly, making it more expensive to run a VFD controlled pump through it's overall range.

But it is funny that we are even comparing a VFD to a control valve. Everybody knows a valve burns energy, right? So if there is only a few percent difference from a VFD to a control valve, the VFD is "burning" almost as much energy as a control valve, not saving energy.

Looking at the pump curve again, you will see the VFD is using 1.96HP to pump 6.5 GPM from 231' of head. 6.5 GPM from 231' only requires a 1/2HP pump. So comparing the VFD to an efficient way to deliver 6.5 GPM at 231' the VFD is wasting almost 400% energy. It would also only take 1/2HP energy for the 10HP to supply 6.5 GPM at 231' when controlled with a pressure tank instead of a VFD. With a pressure tank the 100 GPM, 10 HP pump would only be on 1/20th of the time, which is only using 1/2HP energy and saving nearly 400% over the VFD.

VFD's are not used on centrifugal pumps in industry because of energy or cost savings. Industry always does what makes them the most money, and costs savings to you is not conducive to making them the most money.

A VFD can only save energy when controlling a compressor or some other positive displacement pump, not a centrifugal pump. Letting you believe a VFD is saving energy on regular pumps is just icing on the cake for the manufacturers. That gets you to purchase the most expensive and shortest lived pump control, from which they make the most money.

Once someone has drank the VFD Kool Aid it is like they are in a cult. They will not listen to any facts. Just because everyone in the industry is doing it, they are adamant they are right. It is called "groupthink" when people are convinced they are right because that is what everyone else thinks, even though there is no proof to back it up. These are the people who just get loud instead of posting any facts on the subject. Good conversation though as most engineers can't make it this far with me.