Hello everyone!

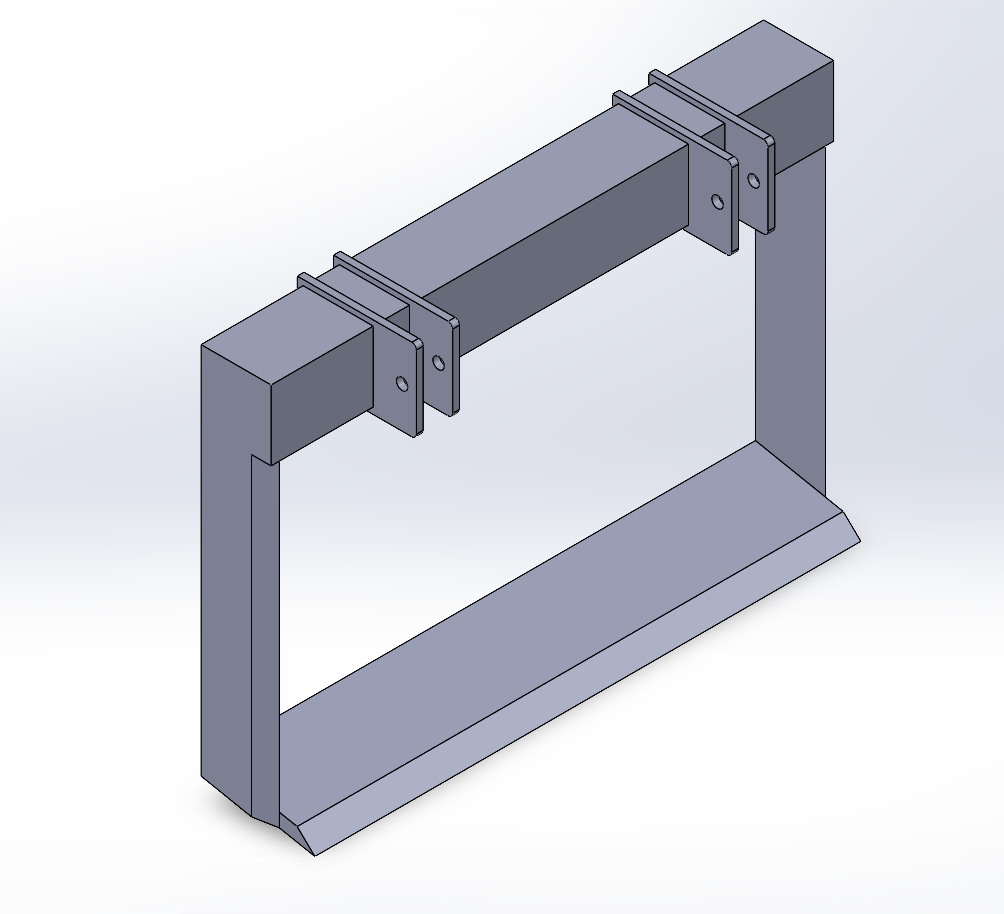

I am planning to build an undercutter/bed lifter tractor attachment. The goal is to slide a slanted board 10-12inch (25-30cm) deep into the ground and lift the soil just enough, so that you don't need to use a shovel to dig out root crops such as garlic or carrots. This is how it looks in action:

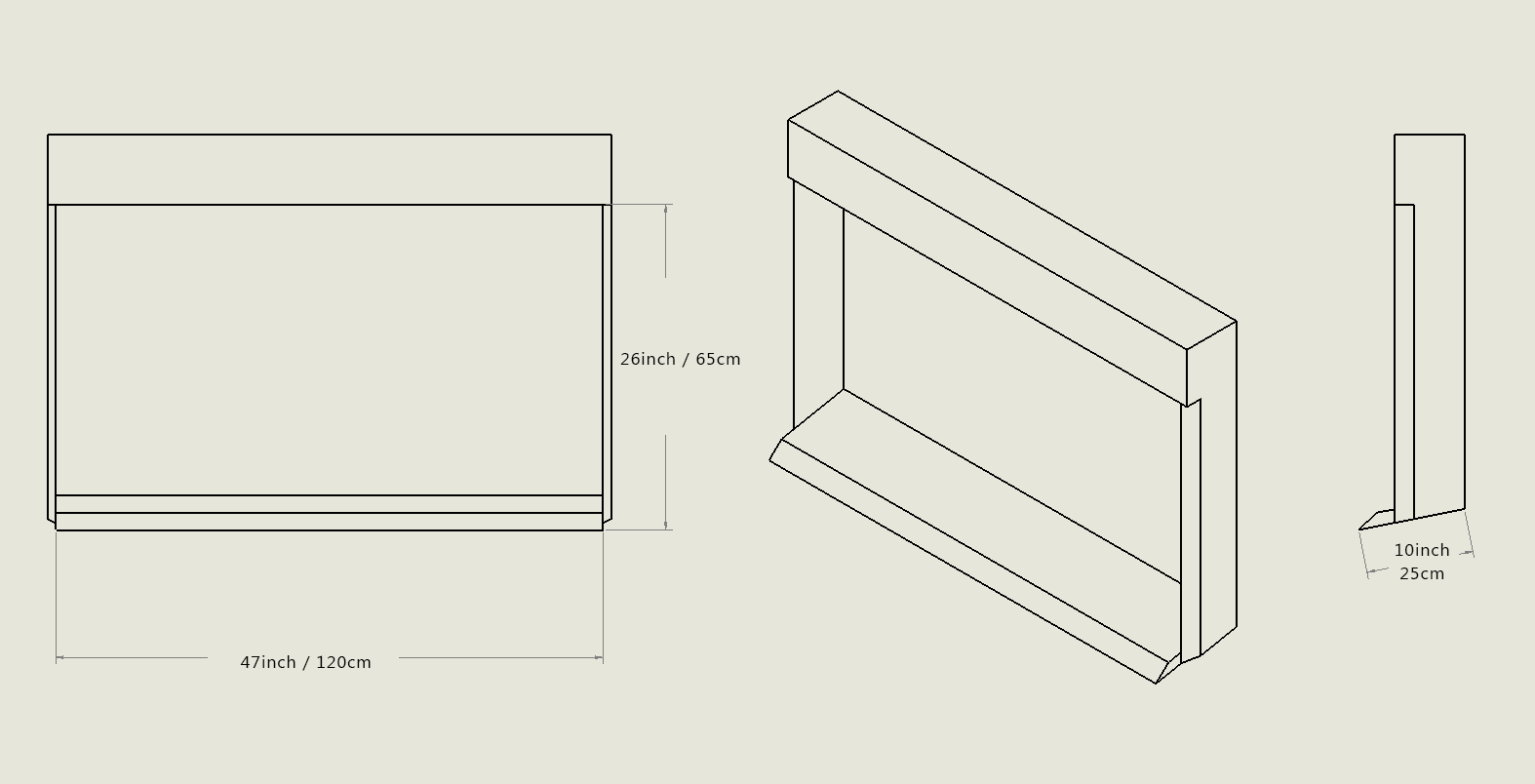

And these are the dimensions (top link arm isn't drawn)

I am unable to asses how thick should the sidewalls and the bottom lifting board be and which steel is best suited for such applications. Can you help me out? Does anyone have an undercutter on the farm and would be willing to measure how thick the steel is?

Thank you for your help!

I am planning to build an undercutter/bed lifter tractor attachment. The goal is to slide a slanted board 10-12inch (25-30cm) deep into the ground and lift the soil just enough, so that you don't need to use a shovel to dig out root crops such as garlic or carrots. This is how it looks in action:

And these are the dimensions (top link arm isn't drawn)

I am unable to asses how thick should the sidewalls and the bottom lifting board be and which steel is best suited for such applications. Can you help me out? Does anyone have an undercutter on the farm and would be willing to measure how thick the steel is?

Thank you for your help!