Piston

Elite Member

In my quest to make my backhoe more useful, I'm thinking about adding a thumb to it.

I added a grapple to my tractor and it was the best thing I've ever done! I can only imagine I'll get a similar feeling with the backhoe. The backhoe in question is an older John Deere 410B, not sure of the year, maybe a 1985, it has a bit over 4,000hrs on it and I'm sure it has a lot of life left in it, as long as I keep using it and don't let it sit and go unused! The more useful it is of course, the more I'll use it :thumbsup:

A quick little rundown on my idea. I work away from home and we have a lot of scrap steel where I work. I can pretty much build the thing with steel that we would otherwise throw away to the scrap bin, plus we have tools at work that I can use that aren't available to me at home. I've checked with my supervisor to make sure it's okay to do this, and he's given me the okay.

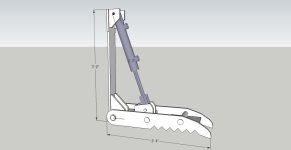

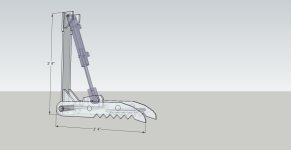

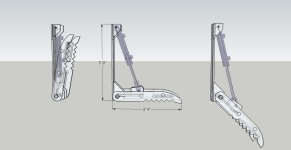

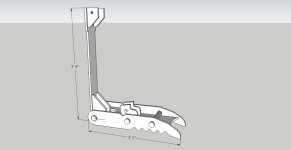

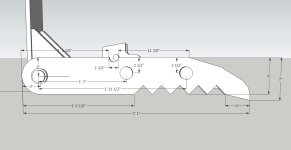

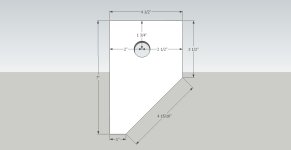

The problem is, I have to ship it home! I estimate it will weigh around 250 lbs by the time I'm done with it. So my plan is to design the thumb using Sketchup, then break it into individual pieces in the drawing, and cut/fit all the pieces, but not weld them. Once I get it home, I will weld it all together.

Not sure if this is going to work or not, but I'm gonna give it a shot (pending one more "okay" from work to use the scrap materials).

I've been looking online at pics and came up with a general sketch of what I'd like, as well as size. I'll post the Sketchup drawing once I get a little more 'finished' with it.

The more I mess with the Sketchup drawing, the more I think about making the thumb hydraulic. I'm curious if someone could give me a very quick and basic rundown on the differences of adding a selector valve to a closed center system, vs an open center system? I've become semi familiar with adding hydraulics to my tractor, (link in my sig) and I feel I could pretty easily do it to the backhoe to, if it isn't much different. I'm not sure about the cost yet though, that will have to be figured once I figure out what the heck I even need :laughing:

Here are a couple pics of the backhoe I will (hopefully) have a thumb for someday. This may be a long drawn out process, and in fact there is a good chance it won't happen at all, but I figure if I post up on here, I'll have more pressure to get it done :laughing:

I added a grapple to my tractor and it was the best thing I've ever done! I can only imagine I'll get a similar feeling with the backhoe. The backhoe in question is an older John Deere 410B, not sure of the year, maybe a 1985, it has a bit over 4,000hrs on it and I'm sure it has a lot of life left in it, as long as I keep using it and don't let it sit and go unused! The more useful it is of course, the more I'll use it :thumbsup:

A quick little rundown on my idea. I work away from home and we have a lot of scrap steel where I work. I can pretty much build the thing with steel that we would otherwise throw away to the scrap bin, plus we have tools at work that I can use that aren't available to me at home. I've checked with my supervisor to make sure it's okay to do this, and he's given me the okay.

The problem is, I have to ship it home! I estimate it will weigh around 250 lbs by the time I'm done with it. So my plan is to design the thumb using Sketchup, then break it into individual pieces in the drawing, and cut/fit all the pieces, but not weld them. Once I get it home, I will weld it all together.

Not sure if this is going to work or not, but I'm gonna give it a shot (pending one more "okay" from work to use the scrap materials).

I've been looking online at pics and came up with a general sketch of what I'd like, as well as size. I'll post the Sketchup drawing once I get a little more 'finished' with it.

The more I mess with the Sketchup drawing, the more I think about making the thumb hydraulic. I'm curious if someone could give me a very quick and basic rundown on the differences of adding a selector valve to a closed center system, vs an open center system? I've become semi familiar with adding hydraulics to my tractor, (link in my sig) and I feel I could pretty easily do it to the backhoe to, if it isn't much different. I'm not sure about the cost yet though, that will have to be figured once I figure out what the heck I even need :laughing:

Here are a couple pics of the backhoe I will (hopefully) have a thumb for someday. This may be a long drawn out process, and in fact there is a good chance it won't happen at all, but I figure if I post up on here, I'll have more pressure to get it done :laughing: