You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a waste oil burning stove for my shop

- Thread starter LetsRoll

- Start date

/ Building a waste oil burning stove for my shop

#71

Donman

Silver Member

- Joined

- Jul 10, 2004

- Messages

- 153

- Location

- Western Michigan

- Tractor

- Yanmar 187D Bobcat 743 skid loader w/forks and homebuilt 6-way grader blade

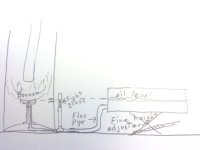

I am in the process of building the water heater tank waste oil heater and the concept of bringing oil up from the bottom of the conical has me really intrigued. I can see all kinds of advantages for doing it that way. I'm thinking of drilling and tapping a hole in the center of the conical for a 3/8" or 1/2" iron pipe and running it down thru the pedistal and out the side at floor level to a tee next to the outside of the heater. The tee would have a short standpipe with a sight glass at the level of the conical burner with marks on the heater tank for high and low burn oil levels. A large surface shallow oil reservoir with a flexible hose connection would stand within view of the sight glass and the reservoir would need a fine tuned height adjuster for maintaining the oil level. The larger the surface of the adjustable height oil reservoir the less often it would have to be adjusted because a 1/8" drop in oil level over a large area would take quite some time and still equal only a 1/8" drop at the burner.

Some of the advantages I can see are the possible elimination of a filter system because there would be no needle valve to plug. Water and contaminates would settle out of the reservoir and could be drained off instead of filtered out. Also the the tank would not have to be raised to create pressure for the needle valve to regulate the flow.

Attached is a drawing of this preliminary idea. I'm sure it needs a lot of tweaking and I'd like to hear some pros and cons.

Some of the advantages I can see are the possible elimination of a filter system because there would be no needle valve to plug. Water and contaminates would settle out of the reservoir and could be drained off instead of filtered out. Also the the tank would not have to be raised to create pressure for the needle valve to regulate the flow.

Attached is a drawing of this preliminary idea. I'm sure it needs a lot of tweaking and I'd like to hear some pros and cons.

Attachments

Berniep

Platinum Member

Wow that's a great idea. Still going to need to clean the burner once in a while so you will need to be able to get at it or remove it easily.

If you add a small pump and sump to the tank you could use a constant overflow type of deal to eliminate adjustments in the height of the supply tank.

If you add a small pump and sump to the tank you could use a constant overflow type of deal to eliminate adjustments in the height of the supply tank.

LetsRoll

Gold Member

I finally finished my stove this past weekend. After I got home from work, I fired up the stove and had two results happen. First one was a total failure and the other one had a sucessful outcome. The first burn test produced a ton of soot. The burn did pretty good, but I didn't like the amount of soot that was forming on the inside of the stove (did not product a clean burn). The second burn turned out really good. I inducted air down the pipe that the oil line was going through. I welded a fitting to the stove and screwed a 3/8 inch pipe to the fitting. Then I ran the oil line through this pipe inside of the stove. You can see this pipe inside of the stove in one of the pictures. This 3/8 inch pipe kept the flame off the oil line. I did not induct to much air cause the fire inside the stove almost doubled and I felt this was not safe. The fire sounded like a jet engine inside of the stove. I only injected the air down the pipe for about 15 minutes and the temperture raised up almost 200 degrees by doing this. You can see in the one picture where the cast iron skillet is (new drip tube picture), the left side of the skillet is totally clean from soot. Inducting the air down the tube blew the oil into a mist which caused the oil to burn eaiser and cleaner and the volume of the flame doubled. I used my air compressor to induct the air down the tube. So, now, I have to find a way to induct air in the path of the oil. I will probably change the 3/8 inch pipe to a 2 inch pipe and start looking for a blower fan and motor so I can induct air and have the oil line drip into the path of the air stream. Doing this allow the oil to burn cleaner and hotter.

The only other things that I have to do is finish getting the green coating off the stove, finish painting the stove and the flue pipe (inside and outside). Hook up the air pressure regulator to the waist oil tank. Finish painting the heat box on the wall and paint those brackets that are bolted to the heat box and paint the bracket that holds the oil tank to the stud on the wall. Pull off the 2x4's off the concrete pad outside. And start looking for a blower motor and a fan for the air induction. After all of this is done, I will be totally finished. And then I will start my next project.

The only other things that I have to do is finish getting the green coating off the stove, finish painting the stove and the flue pipe (inside and outside). Hook up the air pressure regulator to the waist oil tank. Finish painting the heat box on the wall and paint those brackets that are bolted to the heat box and paint the bracket that holds the oil tank to the stud on the wall. Pull off the 2x4's off the concrete pad outside. And start looking for a blower motor and a fan for the air induction. After all of this is done, I will be totally finished. And then I will start my next project.

Attachments

-

Front of Stove.JPG126.9 KB · Views: 1,446

Front of Stove.JPG126.9 KB · Views: 1,446 -

Air Intake Vents.JPG114.2 KB · Views: 1,398

Air Intake Vents.JPG114.2 KB · Views: 1,398 -

New Drip Tube.JPG94.5 KB · Views: 1,846

New Drip Tube.JPG94.5 KB · Views: 1,846 -

Oil Line into Stove.JPG88.2 KB · Views: 1,414

Oil Line into Stove.JPG88.2 KB · Views: 1,414 -

Ball Valve.JPG89.1 KB · Views: 1,146

Ball Valve.JPG89.1 KB · Views: 1,146 -

FronT View Oil Tank.JPG94.1 KB · Views: 1,178

FronT View Oil Tank.JPG94.1 KB · Views: 1,178 -

Mounted Oil Tank.JPG103.9 KB · Views: 1,074

Mounted Oil Tank.JPG103.9 KB · Views: 1,074 -

Closer View.JPG112.1 KB · Views: 1,055

Closer View.JPG112.1 KB · Views: 1,055 -

Flue Pipe.JPG125.7 KB · Views: 1,294

Flue Pipe.JPG125.7 KB · Views: 1,294 -

Heat Box.JPG100.9 KB · Views: 1,312

Heat Box.JPG100.9 KB · Views: 1,312 -

Outside Heat Box.JPG90.4 KB · Views: 1,176

Outside Heat Box.JPG90.4 KB · Views: 1,176 -

Outside Flue Pipe.JPG135.8 KB · Views: 1,140

Outside Flue Pipe.JPG135.8 KB · Views: 1,140 -

Concrete Pad For Flue Pipe.JPG225.4 KB · Views: 1,243

Concrete Pad For Flue Pipe.JPG225.4 KB · Views: 1,243 -

Flue Cap.JPG67.8 KB · Views: 1,157

Flue Cap.JPG67.8 KB · Views: 1,157

Donman

Silver Member

- Joined

- Jul 10, 2004

- Messages

- 153

- Location

- Western Michigan

- Tractor

- Yanmar 187D Bobcat 743 skid loader w/forks and homebuilt 6-way grader blade

Berniep said:If you add a small pump and sump to the tank you could use a constant overflow type of deal to eliminate adjustments in the height of the supply tank.

I like the idea of the small pump and overflow to eliminate constant height adjustment. I really wanted it to operate simply though with no pumps or electricity. I may just experiment with the reservoir height adjustment to see how often an adjustment is necessary. If it lasts 45 minutes to an hour before adjustment is necessary - I can live with that. One nice thing is that oil temperature should not have a great effect on the burn as it does with the drip method and if I do not adjust anything, the oil in the conical will shrink instead of overflow. The reservoir could be filled with a valve from an outside tank or with a five gallon pail and then adjusted up until the sight glass says stop.

Hi guy's

For a simple filling self leveling system how about a second tank for oil storage above the level tank and place a float valve in the leveling tank. You just fill the storage tank the level tank takes care of itself. Of course I'd place the line from the storage tank up off the bottom of the tank a bit and have provisions for a drain to clean out settled crap n water and a saftey valve between the storage tank and the leveling tank incase the float vave messed up. I suppose you could also do the same thing with a pump and a float switch and just stick the suction line in whatever container the oil came in. Just a few thoughts.

Chris

For a simple filling self leveling system how about a second tank for oil storage above the level tank and place a float valve in the leveling tank. You just fill the storage tank the level tank takes care of itself. Of course I'd place the line from the storage tank up off the bottom of the tank a bit and have provisions for a drain to clean out settled crap n water and a saftey valve between the storage tank and the leveling tank incase the float vave messed up. I suppose you could also do the same thing with a pump and a float switch and just stick the suction line in whatever container the oil came in. Just a few thoughts.

Chris

Donman

Silver Member

- Joined

- Jul 10, 2004

- Messages

- 153

- Location

- Western Michigan

- Tractor

- Yanmar 187D Bobcat 743 skid loader w/forks and homebuilt 6-way grader blade

LetsRoll, I noticed in your last post that you are using a cast iron pan and introducing air under some pressure. Did you put the aluminum conical inside the pan or are you abandoning the conical altogether? I can't remember reading in any of your posts that you quit using the liquid vaporizing method.

Donman

Silver Member

- Joined

- Jul 10, 2004

- Messages

- 153

- Location

- Western Michigan

- Tractor

- Yanmar 187D Bobcat 743 skid loader w/forks and homebuilt 6-way grader blade

wheelsc67 said:. . . and a saftey valve between the storage tank and the leveling tank incase the float vave messed up.

Wheelsc67, welcome to the forum! What type of safety valve did you have in mind? One that was manual that we could shut off when we were away or another float type in case the first one plugged?

The conical burner has only a 12 degree slope to it which translates to only about 3/8" to 1/2". I'm thinking that in most burns the middle 1/3 of the depth variation will be used so the float system might just work as well as anything else. Thanks for the input.

P.S. When I was growing up ( my wife sometimes wonders if I ever did) we had an oil furnace with a float type oval shaped carburater that heated our house. I can't remember how that worked with the thermostat but I thought it somehow idled when the thermo was not calling for heat.

LetsRoll

Gold Member

Oil can not be brought up from the center of the conical cause of how HOT the conical will get. The oil will be cooked before it even passes out of the oil line. Plus the oil build up (ash) that will be on the conical. I've only done a few tests and the only way to keep the oil from cooking at the end of the line is air induction. The oil has to drip into the air stream to keep the heat and flame off the end of the oil line. Even thou my oil line is inside of a 3/8" tube, the flame would climb up inisde the tube and go to the end of the oil line. I've alreay had to clean the oil line out of a hard deposits from the oil burning inside the oil line. My oil tank is 7 foot above my stove and I still will need to pressurize the oil tank to get a better flow of oil to the conical (because the oil filter causes restriction in the oil line, restrices the oil flow to the stove). This morning I hooked up my air regulator to the oil tank and adjusted the air to 20 lbs. 20 lbs gave me a good oil flow to the conical.