LetsRoll

Gold Member

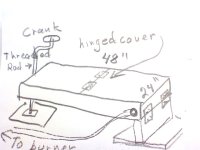

Don, my conical is steel and it is still inside the cast iron skillet. Since I will be going to air induction, I might remachine the conical down. Meaning, make the conical thinner so that it will heat up faster. I put the skillet inside the stove and the conical inside the skillet cause I was testing the air induction on my last test. I was trying to control the path of the oil. I didn't want the oil blowing everywere inside the stove.Donman said:LetsRoll, I noticed in your last post that you are using a cast iron pan and introducing air under some pressure. Did you put the aluminum conical inside the pan or are you abandoning the conical altogether? I can't remember reading in any of your posts that you quit using the liquid vaporizing method.

Thanks,

Cliff