TSO

Elite Member

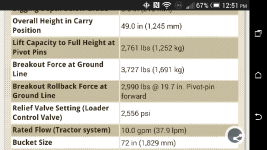

You're thinking too much. I see a wall of green. I'm using the BXpanded bolt on toothblade exactly the way it is supposed to be used on 2" and smaller material. Right before I made the video, as a test I sheared off a 3" pine like it wasn't even there. The stuff you see me hitting repeatedly is a stand of thick poplar. The loader has a breakout force approaching 5,000 pounds and can lift 2900 pounds all the way up. It is a much heavier loader than what is featured on smaller tractors. The whole point of the BXpanded piranha tooth bar is that it has a hardened, serrated, sharpened edge for cutting through material as demonstrated in the final section of their own demo video.

YouTube Link: https://www.youtube.com/watch?v=_sqii2mvSgo

That said, bumping things out of the way is both slower and messier than rotary cutters because you wind up with a pile of dirt and unprocessed material at the end of each push that eventually needs to be cleaned up. I've found it is faster and takes less clean up using a heavy rotary cutter.

Additionally, for those who have paid attention to the My NX6010 thread in the Kioti section, you've probably figured out by now that I can likely fix anything at the Tinkerage.

Just a quick correction on your loader specs ...

And, I have no problem with how you're using your tractor. If you damaged your FEL by doing what folks are complaining about in your video, then my tractor should be broken into several pieces by now.

Just one word of caution though (which many people forget)... While your tractor has a 4 (or is it 5 now?) year warranty, the loader typically only comes with a 1 year. So, if you're gonna break it, make sure to do it in the first 12 months.