GuglioLS

Veteran Member

- Joined

- Feb 13, 2005

- Messages

- 1,155

- Location

- Edgewood, NM USA

- Tractor

- Jinma 354, 1953 Ford NAA Golden Jubilee, Komatsu Bulldozer

I am looking to purchase a used Dozer for road construction on my property. The road will be diagonally cross cut up into the side of a hill that has Lots of rocks & loose dirt. I have looked as several dozer's over the years, mostly Komatsu's D20's & D30's none of which were in very good condition. Well today I visited my favorite used Equipment lot and saw this Komatsu D20A-6 S/N 68449. Of all the Dozer's I have looked at, this one seems to be in the best condition. Price is 12,500. I was hoping to get your opinions of what you think of it's condition and if the price is right. I am not going to rent as I want a dozer to do the road project myself and at my leisure. I may sell it when done or just keep it for future clearing, leveling, & maintenance projects. I do not know all the Dozer terminology so please don't laugh at me to hard.

Here is what I know is in need of some work:

Visual:

The hour meter says 1477, no telling how many times the hour meter has been replaced over the years. I know it's a fairly new hour meter as it's not faded like the Oil pressure gage.

Six Way Blade, works all six ways with little to no slop in the joints. Cutting edge appears in good condition.

Two of the left hydraulic cylinders rods for the blade are pitted, so there are some small hydraulic leaks. The cylinder rods & seals will eventually need to be replaced. Cost? for parts. I can do most, if not all work needed.

The right side cylinders are excellent.

Tracks are nice and tight and seem to be in good condition.

I test drove it:

Engine starts with just a few cranks, it runs smooth, no white or black smoke, Clutch seems fine, breaks work. Turns Left no Problem.

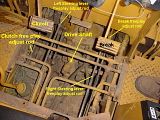

Right turns are another story, when pulling back on the steering lever ALL THE WAY most of the time nothing happens, if you wiggle the lever a little - then it turns to the right no problem. There are several linkages that move and may just be out of adjustment? Sometimes it turns to the right sometimes not, when it does turn, the right track is held tight so I don't think the steering break / clutch needs replacement? not sure.

Anyway here are some pictures for all you experts to take a look at and let me know what you think of it's condition and if the price seems in line with it's age and condition.

Thank you for your input -

Larry

Here is what I know is in need of some work:

Visual:

The hour meter says 1477, no telling how many times the hour meter has been replaced over the years. I know it's a fairly new hour meter as it's not faded like the Oil pressure gage.

Six Way Blade, works all six ways with little to no slop in the joints. Cutting edge appears in good condition.

Two of the left hydraulic cylinders rods for the blade are pitted, so there are some small hydraulic leaks. The cylinder rods & seals will eventually need to be replaced. Cost? for parts. I can do most, if not all work needed.

The right side cylinders are excellent.

Tracks are nice and tight and seem to be in good condition.

I test drove it:

Engine starts with just a few cranks, it runs smooth, no white or black smoke, Clutch seems fine, breaks work. Turns Left no Problem.

Right turns are another story, when pulling back on the steering lever ALL THE WAY most of the time nothing happens, if you wiggle the lever a little - then it turns to the right no problem. There are several linkages that move and may just be out of adjustment? Sometimes it turns to the right sometimes not, when it does turn, the right track is held tight so I don't think the steering break / clutch needs replacement? not sure.

Anyway here are some pictures for all you experts to take a look at and let me know what you think of it's condition and if the price seems in line with it's age and condition.

Thank you for your input -

Larry

Attachments

-

Side View.JPG71.1 KB · Views: 5,234

Side View.JPG71.1 KB · Views: 5,234 -

Back View.JPG81.3 KB · Views: 2,527

Back View.JPG81.3 KB · Views: 2,527 -

Back Blade View 1.JPG82.4 KB · Views: 1,921

Back Blade View 1.JPG82.4 KB · Views: 1,921 -

Back Blade View 2.JPG73 KB · Views: 1,736

Back Blade View 2.JPG73 KB · Views: 1,736 -

Front View.JPG69 KB · Views: 1,881

Front View.JPG69 KB · Views: 1,881 -

Left Engine.JPG56.2 KB · Views: 1,881

Left Engine.JPG56.2 KB · Views: 1,881 -

Right Engine.JPG48.1 KB · Views: 1,664

Right Engine.JPG48.1 KB · Views: 1,664 -

Left Front Track.JPG80.5 KB · Views: 1,602

Left Front Track.JPG80.5 KB · Views: 1,602 -

Left Rear Sprocket.JPG68.7 KB · Views: 1,988

Left Rear Sprocket.JPG68.7 KB · Views: 1,988 -

Right Front track.JPG80.7 KB · Views: 1,872

Right Front track.JPG80.7 KB · Views: 1,872 -

Right Rear Sproket.JPG69.7 KB · Views: 1,941

Right Rear Sproket.JPG69.7 KB · Views: 1,941 -

Pitted Cylinder Rod 1.JPG57.8 KB · Views: 1,980

Pitted Cylinder Rod 1.JPG57.8 KB · Views: 1,980 -

Pitted Cylinder Rod 2.JPG67.4 KB · Views: 1,972

Pitted Cylinder Rod 2.JPG67.4 KB · Views: 1,972