Freakingstang

Gold Member

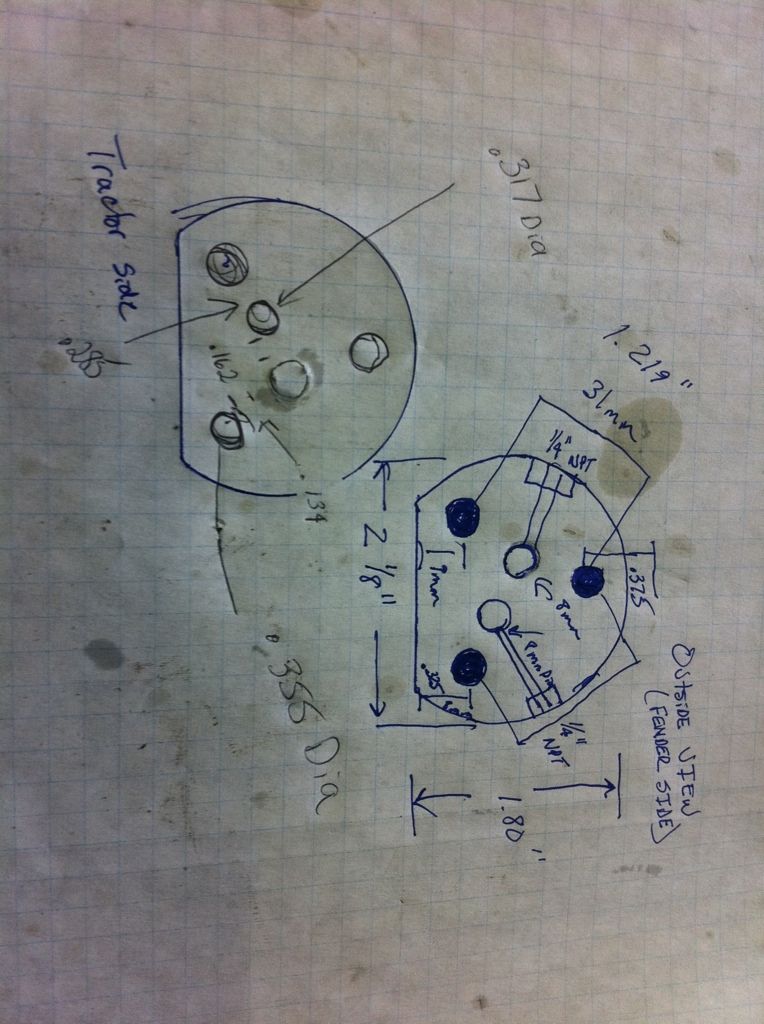

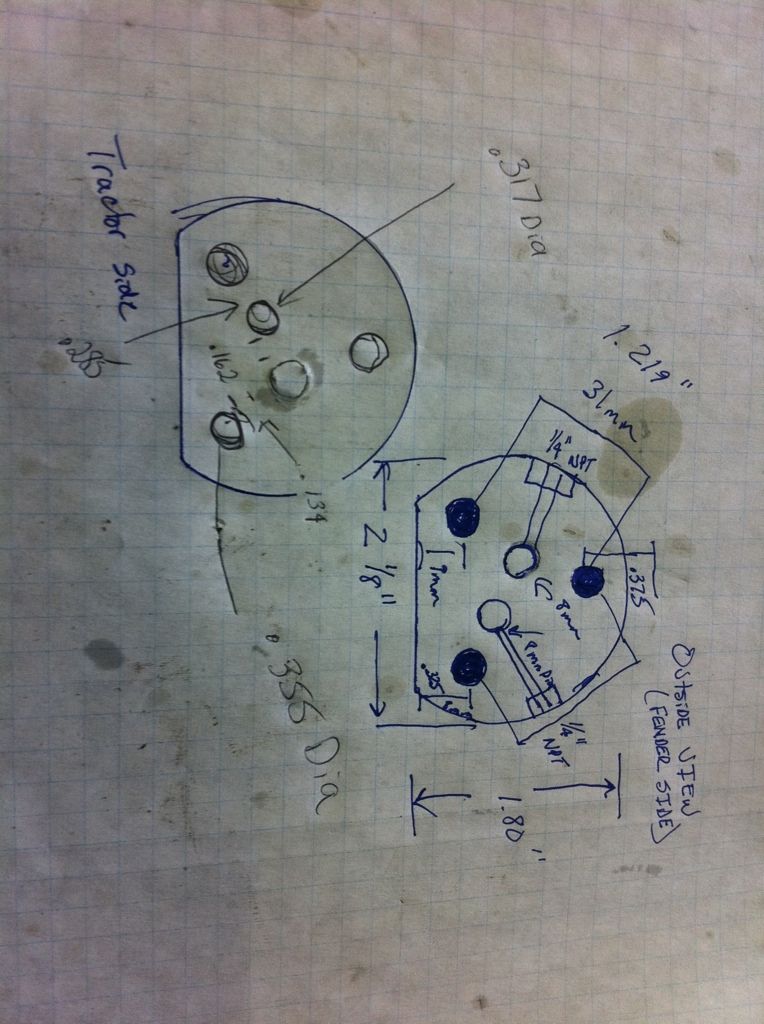

I started making my own.... Took some measurements. I had a junk cylinder from an air compressor at work that already had one 3/8npt threaded hole. I lined up the cross hole and cut some meat out and marked my

Holes...

Just gotta clean it up and run a pipe tap down it and I should be good to go.... Now I'm just waiting on my power beyond plug to show up...

Holes...

Just gotta clean it up and run a pipe tap down it and I should be good to go.... Now I'm just waiting on my power beyond plug to show up...