I am building a new driveway and need to know if it is better to use steel mesh or is fiber in the concrete as good. it is being built on an existing pad that is made of clay topped with 2's and 304. it is very stable and large trucks drive on it all the time with no problems. the concrete will be 4" thick. Thanks for your help!!!

People, think about this a little. Take a good look at the next concrete structure, bridge or highway overpass that you see being built and use what you see. You won't see rebar being wasted by being installed in the center of anything. It only has value when it is near the surface of the concrete.

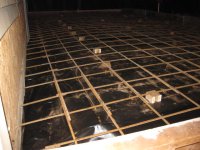

Rebar and mesh do nothing for concrete if it is centered in the slab, it just prevents it from pulling apart if it happens to crack. If you point load a slab such as driving a large truck with 20k weight on the front axel, the slab will try to deform.

You will have 10k of weight sitting on a very small area where the tire contacts the concrete. The top half of the slab will be under compression both from the weight of the tire and the bending down will impose radial compression from the resulting deflection. Any reinforcing that is centered in the slab will be in a zone of nuetral stress.

The area above is under compression and the area below is under tension and the area with the reinforcement will be doing nothing, it is centered and it doesn't see any stress other than a bending force that it is unable to resist. Rebar and wire are very soft and easy to bend. The Value of these reinforcements is only achieved when they are near the top and the bottom of the slab.

In the above example if the wire or rebar is located near the bottom of the slab when the truck drives over it, it becomes in tension and its strength of 36,000lbs per sq inch will aid in preventing the slab from deflecting. It is very easy to bend, but it is very hard to stretch, that is where it's strength lies. By the same token if it is near the top of the slab, when the frost heaves the floor from below having it near the surface is the place you would want it.

That being said, the reason that the fiber works so well is that it is everywhere to resist loads from both above and below.

Reinforcing that is centered in the slab does nothing to prevent it from cracking it just stops it from pulling apart after it has cracked and it there is enough of it the shear strength maintains the edges of the cracks at the same elevation.

Many good concrete contractors don't know this. They are not engineers, they are just hard working people who try to do the best job the can and they do mean well. Their fathers told them this is the way it should be.

I recently had my barn floor expanded and the contractor thought he did me a good job by installing rebar dowelled in at the center of the old slab that tied into my new work. But the best thing he did for me was to order the concrete with fiber in it.

I am not a civil engineer, just an undereducated and out of work mechanical designer, but I do have a good grasp of how things work. Stress doesn't care if it is in concrete or steel it all acts the same. The area of nuetral stress is always centered in the material that is being deflected. That is the area that will benifit the least from reinforcement.

So don't get your knickers in a knot if your reinforcing wire ends up not being centered in the slab. It is probably the best thing that could ever happen to your project.

I just had to say that........My concrete guy did the best job he knew how to do. He has been working hard for 25 years laying concrete. They just don't know unless you tell them.

That is why designed projects have the position of the concrete reinforcements dimensioned into the plan. The location makes a big difference. Using fiber makes it almost fool proof.