rsallen

Platinum Member

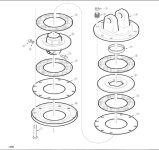

Honestly don't know exactly how a slip clutch works but I assume that what I'm looking at is bearings that allow some 'flex' or give between the drive shaft and the working end (ie. the blades).

If that's the case before I rewelded anything I'd dismantle (loosen) the spring tension and make sure those bearings were still free and not frozen because if they're not rewelding the drive shaft would be as useless as the last repair done or not done as the case may be.

And yes, one should always return barrowed equipment in better shape somehow than when it's loaned even if it's just a bit of grease needed.

If that's the case before I rewelded anything I'd dismantle (loosen) the spring tension and make sure those bearings were still free and not frozen because if they're not rewelding the drive shaft would be as useless as the last repair done or not done as the case may be.

And yes, one should always return barrowed equipment in better shape somehow than when it's loaned even if it's just a bit of grease needed.