jgreen

New member

Hi Folks,

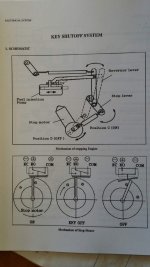

I have a 2004 year and model 2810 that the fuel cutoff solenoid is burned up. First one died/burned up three months ago, replaced with aftermarket solenoid and this past Saturday the replacement burned up. I have the manuals and they do not give a lot of diagnoses and the wiring diagrams are next to useless. What I have done so far: Checked fuel cutoff timer, with key in run position, high/battery voltage for appx. .5 to 1 second to activate pull in coil on fuel solenoid,then 0 volts, appears to be working as designed. Hold in coil circuit maintains voltage to the hold coil. Plan to borrow a inductive amp probe and read amps from relay this week. Fuel solenoid relay (70 amps) appears to be working at this time, unsure if contacts stuck closed and caused excessive time/amperage to fuel solenoid. I found a relay and plan on replacing asap (cheap insurance), but would not like to buy many more of the fuel cutoff solenoids as they are $$$$. Great tractor so far and was just bragging a week ago how it has given very little issues and great performance. Any other ideas or better diagnosis or wiring information would be a help! Any ideas on suppliers for fuel cutoff solenoid?

Thanks,

I have a 2004 year and model 2810 that the fuel cutoff solenoid is burned up. First one died/burned up three months ago, replaced with aftermarket solenoid and this past Saturday the replacement burned up. I have the manuals and they do not give a lot of diagnoses and the wiring diagrams are next to useless. What I have done so far: Checked fuel cutoff timer, with key in run position, high/battery voltage for appx. .5 to 1 second to activate pull in coil on fuel solenoid,then 0 volts, appears to be working as designed. Hold in coil circuit maintains voltage to the hold coil. Plan to borrow a inductive amp probe and read amps from relay this week. Fuel solenoid relay (70 amps) appears to be working at this time, unsure if contacts stuck closed and caused excessive time/amperage to fuel solenoid. I found a relay and plan on replacing asap (cheap insurance), but would not like to buy many more of the fuel cutoff solenoids as they are $$$$. Great tractor so far and was just bragging a week ago how it has given very little issues and great performance. Any other ideas or better diagnosis or wiring information would be a help! Any ideas on suppliers for fuel cutoff solenoid?

Thanks,

Last edited: