Code54

Elite Member

- Joined

- Aug 20, 2005

- Messages

- 4,322

- Location

- Putnam Co. West Virginia

- Tractor

- Kubota MX5100, Kubota BX25D,1957 Farmall Cub Lo-Boy Kubota KX91-3, BCS 853

I was going to 3d print a die holder for the garage but am sort of stumped on how to get holes in a plate that are even. What I am trying to do is make a flat piece of plastic where they sit.

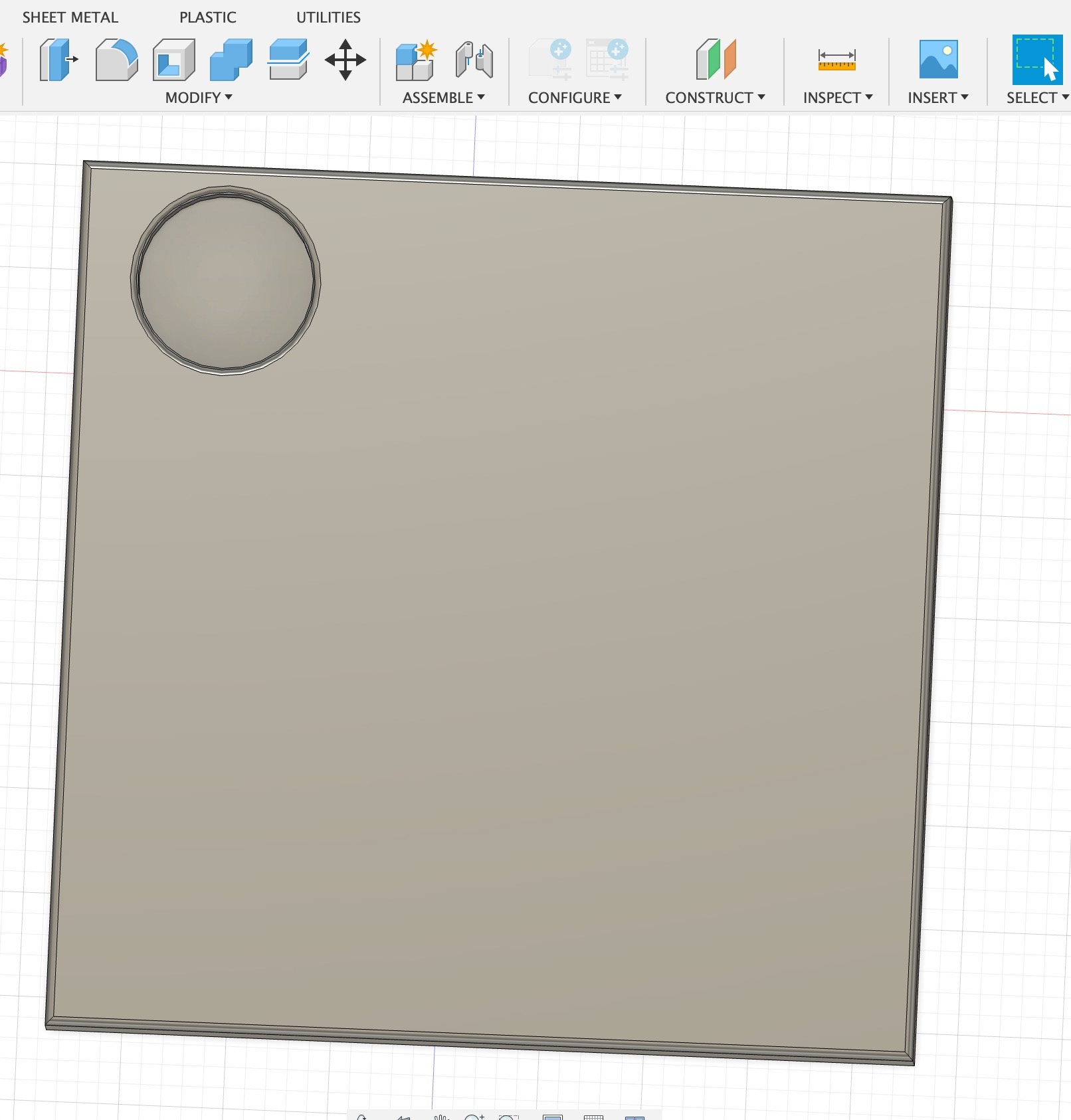

I designed it so it holds 16 total dies, 4 across, 4 down. I can get the first hole (44mm wide at the top, with a 2mm counter sunk edge making the hole 42mm wide by 9mm deep) in the base plate which is 208mmx208mmx14mm thick. My problem is getting the next 15 placed so they are nice and even. I have tried "Aline", tried patterns, and even single holes and cant get it to work right. I even went to TinkerCad and played around and could get it lined up better but the holes are not really perfect circles for some reason so I figure I am far better off in Fusion 360.

Can anyone give me some pointers or explain (like you are talking to a 6-year-old, that is trying to learn Fusion 360) how to do this? I have watched a few videos but nothing seems to work like it is being explained. Sometimes I don't even have the same screen prompts/options that they are mentioning.

I have a STL file, and an F3D file but I cant seem to post them here.

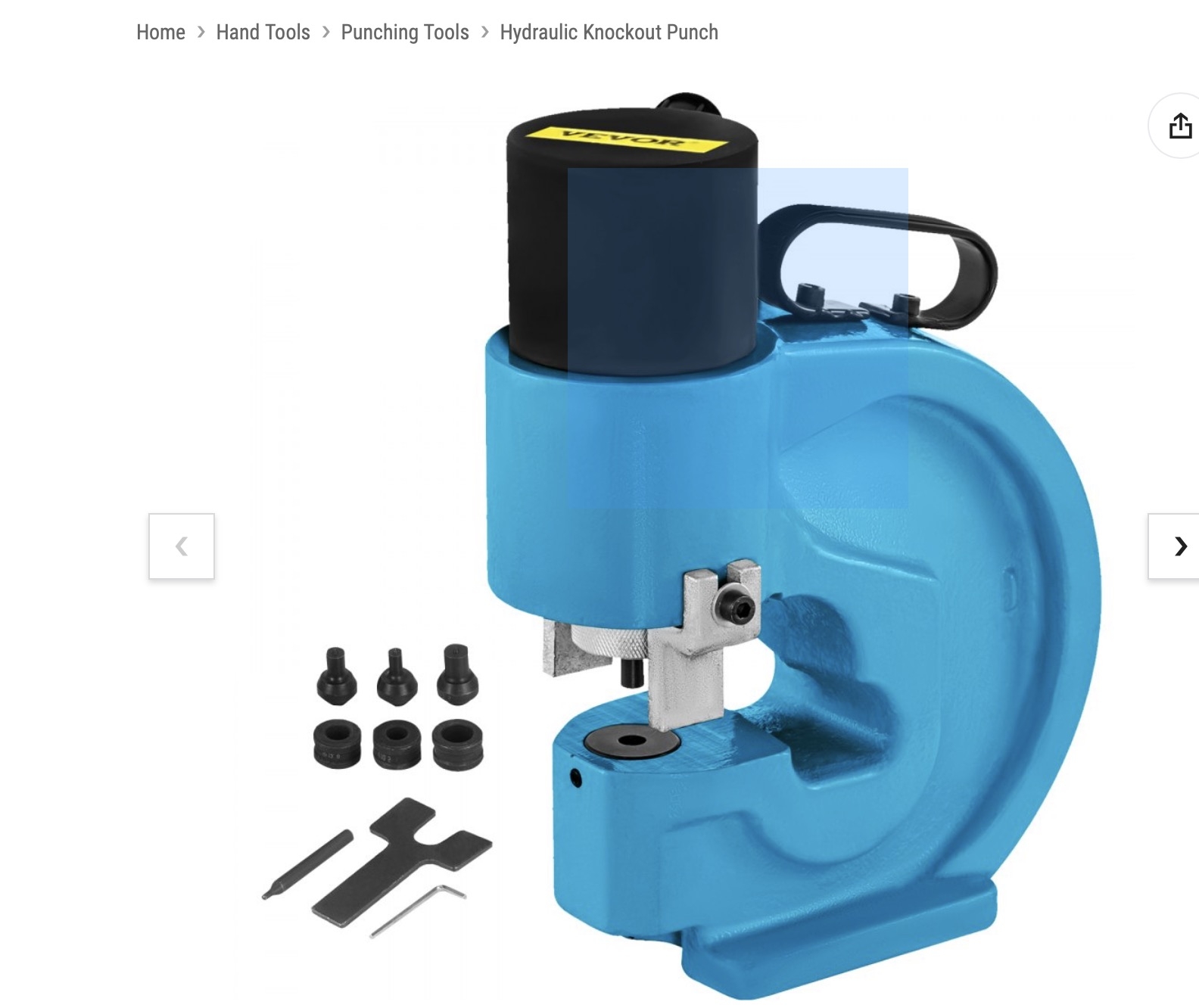

Also if I ever get this correct - anyone that wants the file is welcome to it. It will hold punches for a CH-70 hydraulic punch press.

Here are the punch(s) I want a tray for and here is basically what my design looks like

I designed it so it holds 16 total dies, 4 across, 4 down. I can get the first hole (44mm wide at the top, with a 2mm counter sunk edge making the hole 42mm wide by 9mm deep) in the base plate which is 208mmx208mmx14mm thick. My problem is getting the next 15 placed so they are nice and even. I have tried "Aline", tried patterns, and even single holes and cant get it to work right. I even went to TinkerCad and played around and could get it lined up better but the holes are not really perfect circles for some reason so I figure I am far better off in Fusion 360.

Can anyone give me some pointers or explain (like you are talking to a 6-year-old, that is trying to learn Fusion 360) how to do this? I have watched a few videos but nothing seems to work like it is being explained. Sometimes I don't even have the same screen prompts/options that they are mentioning.

I have a STL file, and an F3D file but I cant seem to post them here.

Also if I ever get this correct - anyone that wants the file is welcome to it. It will hold punches for a CH-70 hydraulic punch press.

Here are the punch(s) I want a tray for and here is basically what my design looks like