TMGT

Elite Member

In Dec. I bought a used L3240, also picked up a ditch bank flail mower. The tractor didn't have any rear remotes so I checked with the dealer first as they the remotes are pretty integrated on this model, unless you just want to bolt a valve to the ROPS, which I didn't want to do.

Dealer wanted $2500+ for 3 remotes (2 float) which probably isn't too bad, but the stories of excessive leakdown and the fact that they couldn't even even order them at the time due to parts shortages made me decide to build my own.

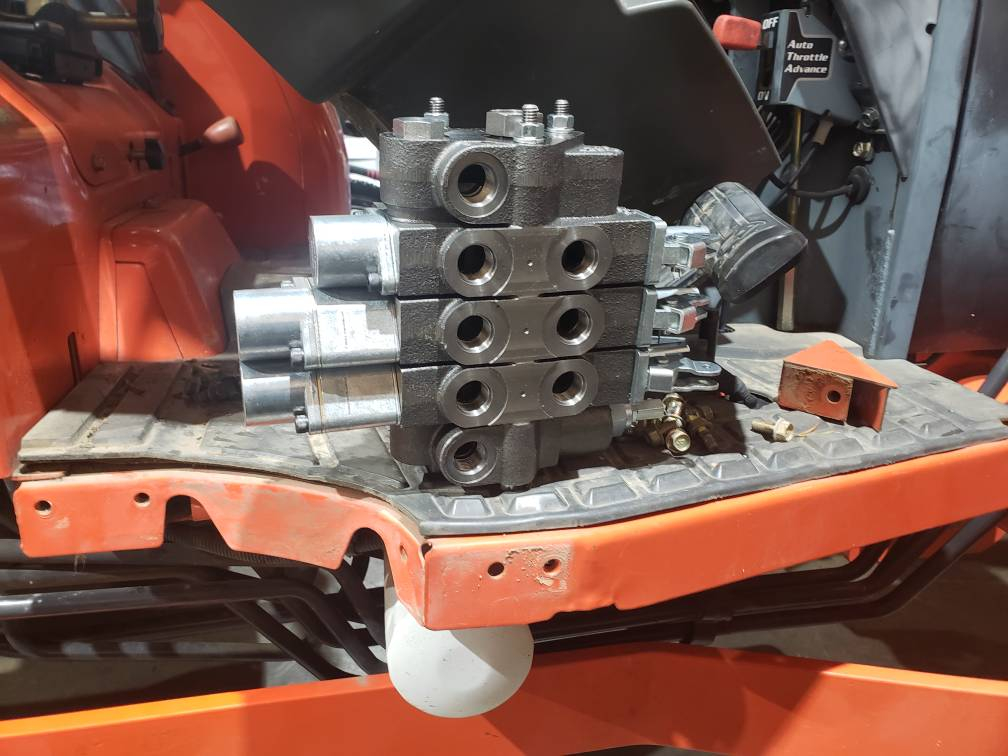

I decided to go with Prince SV sectional valves, 2 float and 1 double acting.

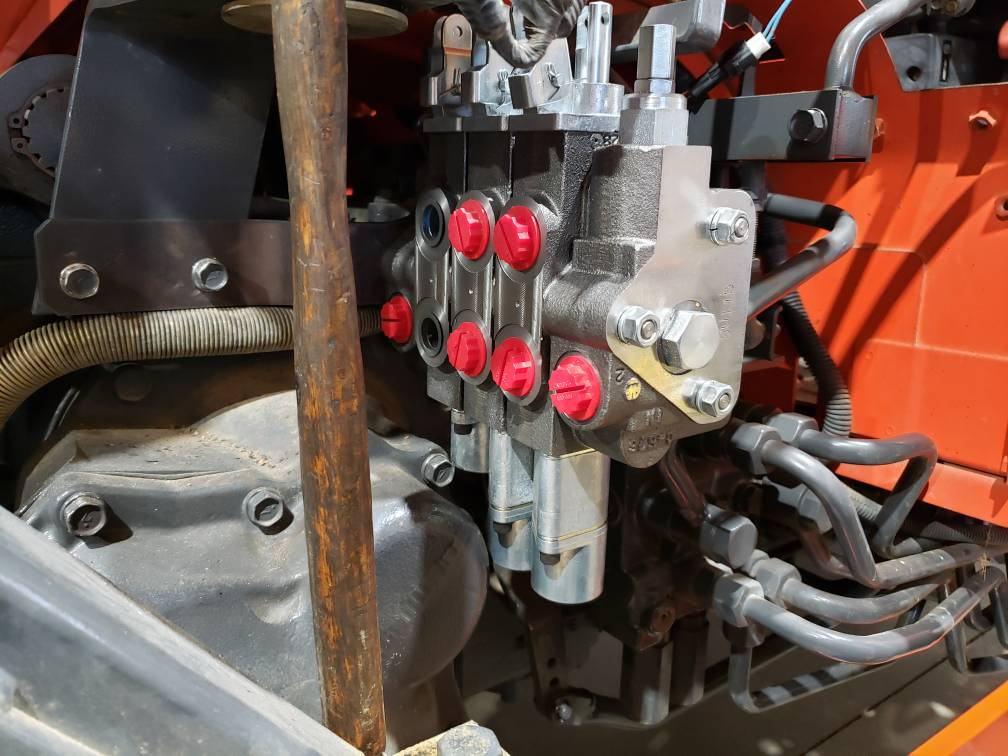

It's a decent size valve and took some trial and error to get it to fit under the operators station, the bracket is 5/16 (because I have a lot of it laying around) and mounts off the through bolts for the valve. It mounts to the rear axle housing using the mounting points for the rear of the operator platform.

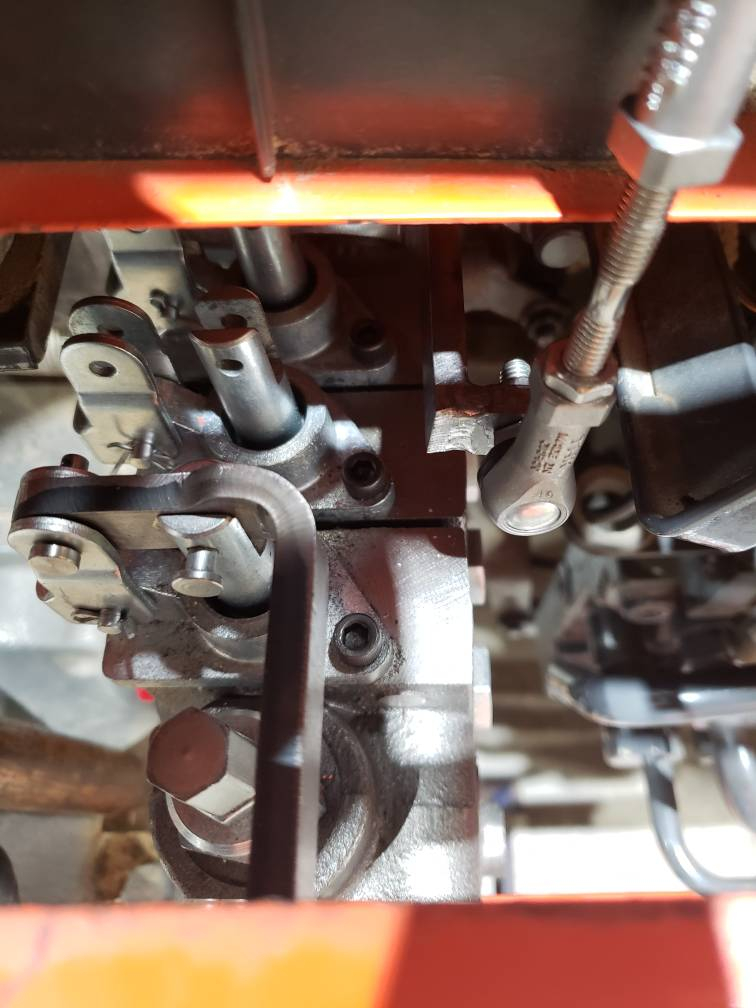

Next was figuring out how to get the linkages over to the small opening where the levers were going to be, most of the valve actually sits under the operators station! There was some trial and error but luckily the plasma table made life a lot easier duplicating parts and making small changes.

I used a sealed studded ball joint type rod end, this proved to make things more difficult as they are bulkier then the factory flat steel bar on a pin.

It took some finessing, but was finally able to make them all fit.

Dealer wanted $2500+ for 3 remotes (2 float) which probably isn't too bad, but the stories of excessive leakdown and the fact that they couldn't even even order them at the time due to parts shortages made me decide to build my own.

I decided to go with Prince SV sectional valves, 2 float and 1 double acting.

It's a decent size valve and took some trial and error to get it to fit under the operators station, the bracket is 5/16 (because I have a lot of it laying around) and mounts off the through bolts for the valve. It mounts to the rear axle housing using the mounting points for the rear of the operator platform.

Next was figuring out how to get the linkages over to the small opening where the levers were going to be, most of the valve actually sits under the operators station! There was some trial and error but luckily the plasma table made life a lot easier duplicating parts and making small changes.

I used a sealed studded ball joint type rod end, this proved to make things more difficult as they are bulkier then the factory flat steel bar on a pin.

It took some finessing, but was finally able to make them all fit.