Really appreciate all the tips. I guess there’s more than one way to skin a cat as they say. Good news. Stuck bolt finally came loose after several days. Kept soaking it. Used the 50-50 mix ATF and acetone. Squared off the edges of the bolt with a dremel. Tapping with hammer and turning with vice grip. Finally heated it up with a torch, not to the red hot, but just to where it was smoking a bit. Not sure which of these was most critical but bolt is out. Now I just have to put everything back together again. LOL.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flail Mower Any Ford 918H owners?

- Thread starter FF191

- Start date

/ Any Ford 918H owners?

#21

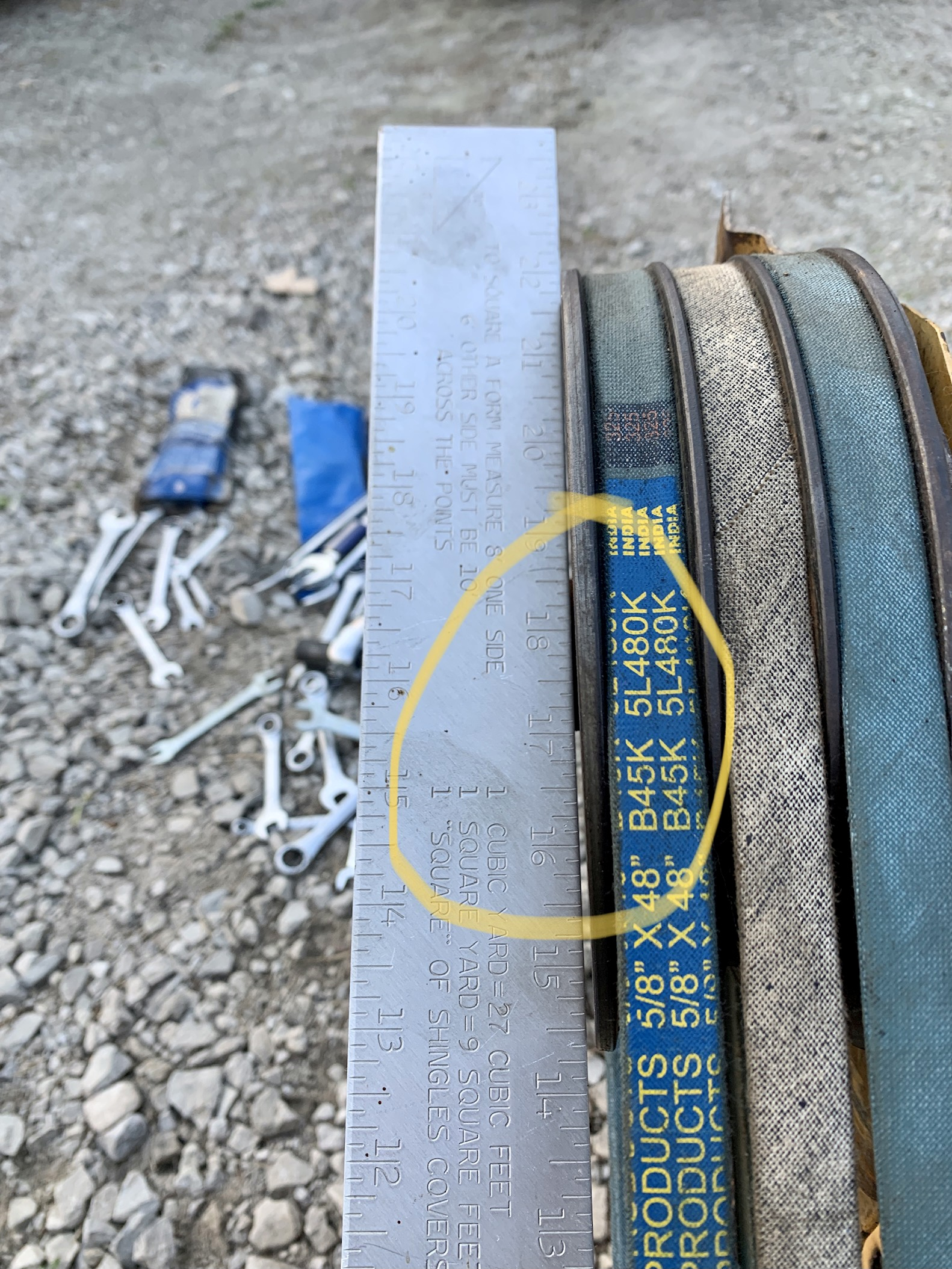

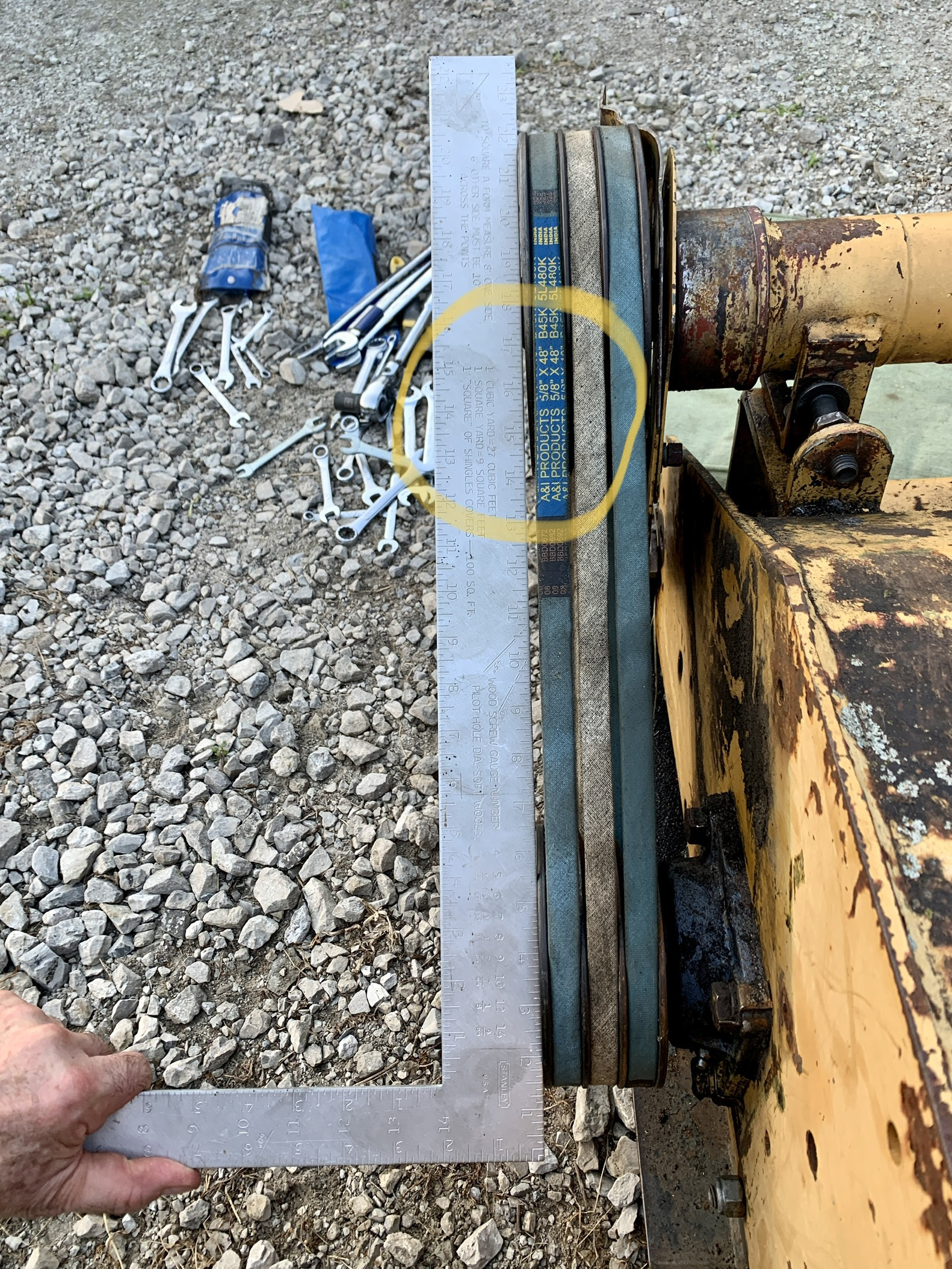

So I’ve got it all together but when I put a straight edge on these two pulleys there’s a slight gap on the top pulley. What would be the way to straighten this out if it’s even necessary. I’ve messed around with the jam bolts

but it doesn’t seem to do much.

but it doesn’t seem to do much.

the old grind

Super Member

- Joined

- Jul 21, 2012

- Messages

- 5,091

- Location

- Mid-Michigan

- Tractor

- NH T-1520 HST, NH TC33DA HST, Case DX26 HST, .Terramite T5C, . NH L785

Just a long-shot here but I hope you'll plan to check belt tension routinely. I do and grease per job, usually lasts per job. Changing belts isn't as big a deal as paying for them. I keep spare sets on hand.

Any comment about the alignment issue?? Also, do you have this particular mower. The manual shows the belt spec as being 5/8 by 48.8“. Obviously that’s an odd size. All the big box stores carry 48 inch. Does that .8 make any difference.

the old grind

Super Member

- Joined

- Jul 21, 2012

- Messages

- 5,091

- Location

- Mid-Michigan

- Tractor

- NH T-1520 HST, NH TC33DA HST, Case DX26 HST, .Terramite T5C, . NH L785

If our belts/sets are same 'size' it's really just a matter of having room/range to adjust. (bolt slots) Again, my OEMs are 69.5" and I'm also using both 69" and 70" which cost ~half as much for good ones at TSC. I wouldn't be afraid to try 48" or 50" if something between is spec'd. One size may be tougher to put on, one may have less room to adjust for wear.

Yeah, probably why it was more of a struggle to get them on then what others here said it would be. ( one guy even said he doesn’t even loosen the gear box bolts—don’t see how that would even be possible).

how about the alignment issue? how critical is that. I mean they are “pretty straight” and mower seems to run smooth. But do I risk ruining the bearing if it’s 2 mm off??

how about the alignment issue? how critical is that. I mean they are “pretty straight” and mower seems to run smooth. But do I risk ruining the bearing if it’s 2 mm off??

John0829

Veteran Member

The gearbox needs to go toward the back of the mower while the pulley end needs to go toward the front. It will get straight, just takes some playing with to get there and keep the tension right.

The .8 difference won't matter as long as they are matched belts and you can get them on.

The .8 difference won't matter as long as they are matched belts and you can get them on.

So originally I could put a straight edge and line up points A CD. But that obviously meant that the top pulley was canted in a little bit. And that was generating way too much heat when I ran it. I can’t get all 4 points aligned. The best I can do is get AB perfectly parallel to CD but that leaves the drive shaft pulley about 3/16 inch inward (to the right) compared to the lower pulley. The jam bolts just allow movement forward and back, not left and right. I don’t see how it’s possible to move that top pulley out toward the left and keep it parallel.

John0829

Veteran Member

I would add shims under the pulley end to eliminate or reduce the cant of the pulley. Lastly you can add some shims between the extension tube and gearbox if you need the pulley more to the left after you have figured what is needed to get the cant out of it.

How hot would you normally expect the pulley to get after running it for about 20 minutes? I’m getting a reading of about 195F. That seems pretty hot but I’ve got no reference point on this. I’m assuming the geometry of the pulleys must have been like this before I put on the new belts so seems like I must’ve been running the mower like this for years. I do notice that the pulleys are held on by hex bolts. Would adjusting the position of the pulleys on the shaft make more sense than using shims?