lakeside

Silver Member

- Joined

- Sep 4, 2008

- Messages

- 227

- Location

- Ontario and Quebec

- Tractor

- B26, G11000 generator and a G1800

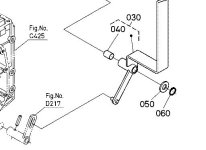

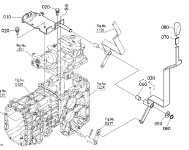

I need some help. My B26 with 500 hours has a problem with the high/Low transfer lever. I was blowing snow on a hill when I tried to go up the grade. The engine bogged down even though the lever was in mid range. I finally made it up the hill and then into my garage. When I looked, the transfer case was in high and the lever had come disconnected. I don't see a hole for a cotter pin or a groove for a retaining ring. I got the lever pin into the transfer lever but it came out again today.

I can't believe Kubota would design something like this without some means of ensuring the parts stay together. There doesn't appear to be anything missing or broken. I tried drilling a hole for a cotter pin but the lever pivot is really hard to get at unless I take the left tire, mud guard and left reflector off. That's a lot of work in my cramped but heated garage. At -7c outside I don't want to take half my tractor apart in the snow.

Any suggestion??

I can't believe Kubota would design something like this without some means of ensuring the parts stay together. There doesn't appear to be anything missing or broken. I tried drilling a hole for a cotter pin but the lever pivot is really hard to get at unless I take the left tire, mud guard and left reflector off. That's a lot of work in my cramped but heated garage. At -7c outside I don't want to take half my tractor apart in the snow.

Any suggestion??