briandantz

Member

- Joined

- May 16, 2015

- Messages

- 46

- Location

- stillwater, ny

- Tractor

- 2013 Kubota L3200 HST w FEL quick attach bucket, forks and BH77 Hoe with Hydro Thumb

I was out stacking wood... thinking.... " I bet I am going to see some Photos from Bump"!

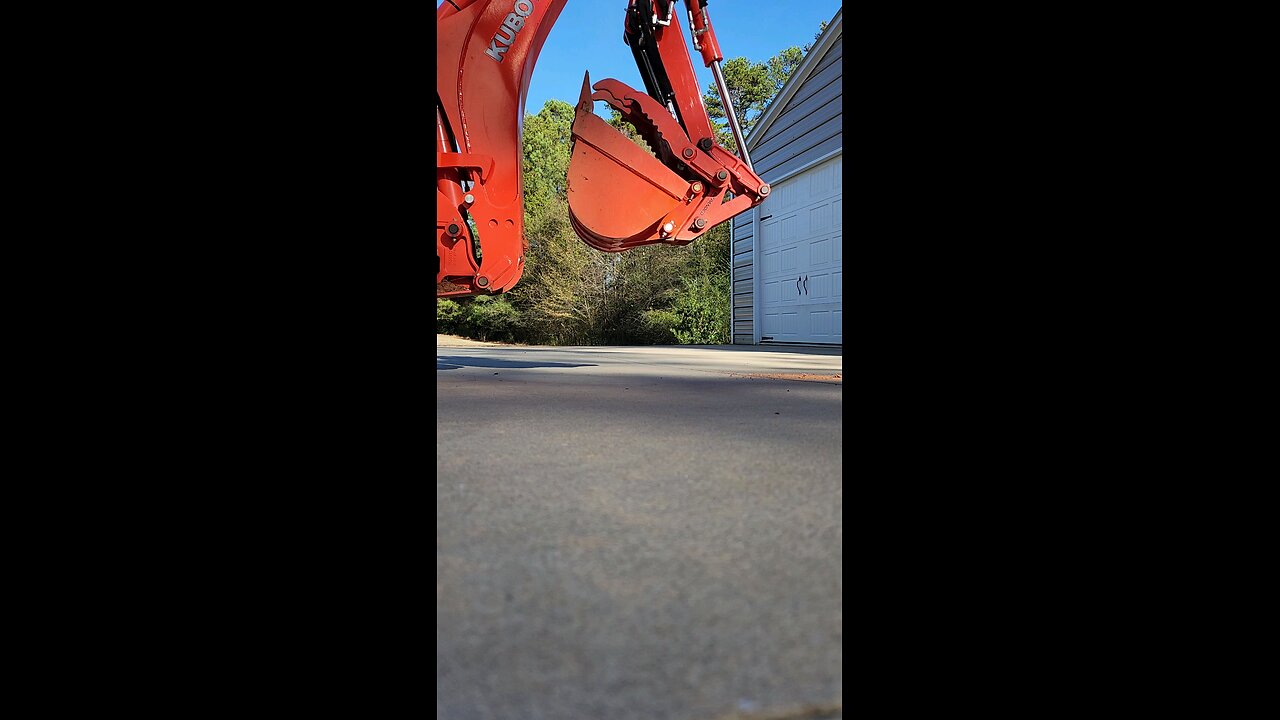

1) Two inches extra really pushed the thumb around.

2) I see you added your spacer, very nice. The side port is out from behind the bracket now too (if you ever need to get to it) and the thumb is plenty clear of the cylinder.

3) i still haven't installed my solenoid cover yet. No good reason why, just busy.

4) Nice ripper, heavier duty than I expected. Real nice.

5) See the wear mark on the thumb about two inches down from the wrist pin (about halfway between the pins)? Another Kubota free feature. I think the base of the thumb hits the bucket when you go closed before the tips touch. I have the same problem starting. I will mark mine with a Sharpee marker tomorrow and show you where the interference is. This is a Kubota design error and has nothing to do with the Hydro addition. They hit with the Manual linkage too.

I have to start using Photobucket . Your photos post so much better. I also owe you some photos of my new Android App Mini Mill DRO i just built. "DRO on the Cheap".

1) Two inches extra really pushed the thumb around.

2) I see you added your spacer, very nice. The side port is out from behind the bracket now too (if you ever need to get to it) and the thumb is plenty clear of the cylinder.

3) i still haven't installed my solenoid cover yet. No good reason why, just busy.

4) Nice ripper, heavier duty than I expected. Real nice.

5) See the wear mark on the thumb about two inches down from the wrist pin (about halfway between the pins)? Another Kubota free feature. I think the base of the thumb hits the bucket when you go closed before the tips touch. I have the same problem starting. I will mark mine with a Sharpee marker tomorrow and show you where the interference is. This is a Kubota design error and has nothing to do with the Hydro addition. They hit with the Manual linkage too.

I have to start using Photobucket . Your photos post so much better. I also owe you some photos of my new Android App Mini Mill DRO i just built. "DRO on the Cheap".