Gordon Gould

Super Member

- Joined

- Apr 1, 2007

- Messages

- 6,236

- Location

- NorthEastern, VT

- Tractor

- Kubota L3010DT, Kubota M5640SUD, Dresser TD7G Dozer

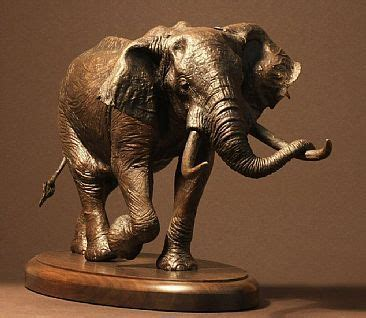

Thanks for the replies - some good ideas. I suggested silver solder the first time and he said that he would prefer I don't use solder ??? he's an artist..... I should have shown the front which is 3 dimensional not a simple plaque so it is to thin to drill and tap in many places. I have seen other stuff he does with bosses and/or drilled and tapped holes. He said he mounts these simple plaques all different ways and sometimes needs them flat on the bottom. I like the carbon sticks idea it will save me some cleaning with the bottom tap.

I only work on his crude stuff - thank goodness.

gg

I only work on his crude stuff - thank goodness.

gg