EddieWalker

Epic Contributor

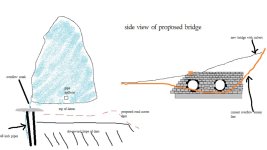

Maybe I miss understood. Is this for the overflow of a pond or a culvert in a creek/ditch? If it is in a pond, the water will work it's way down the side of the pipe unless you specifically seal it. If it's a culvert, like in the pictures posted, go for it. I have done this with several culverts, both at the entrance into it and where the water exits the pipe. I prefer 50 or 60 pound sacks over 80. It's a lot cheaper, lighter and nearly the same coverage. Just not as deep, but that's not gonna matter. After stacking them, I pound the rebar through them. Dry sacks are real easy to get rebar through with a hammer.