gwisejr

New member

Good morning,

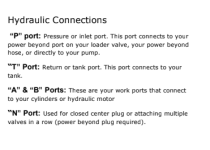

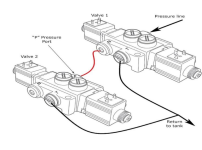

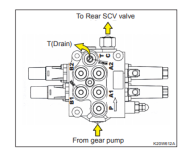

I bought a Branson 3520H a couple weeks ago and I plan on installing a third function valve kit to run a grapple. I've not decided on the kit to buy but trying to understand how they are connected, I'm still a little unclear. They all connect to the Power Beyond port but then the general instructions are to run the T port to the return line/tank reservoir. I'm reading between the lines and assuming that if there is already a hose plugged into the PB port on the main loader valve running to the rear PTO, the third function valve kit is simply placed in series.

Original: Main Loader Valve PB-> Rear PTO

Modification: Main Loader Valve PB->third function valve kit P port-> valvekit T port-> original rear PTO line.

Is this correct or am I totally off base in my understanding?

BTW - for some background, I've purchased a 5 acre lot with about 1.5 acres of trees and brush that I want to clear off. The immediate need is to help load the logs that I've already cut down on to a portable sawmill but long term just helping to clear the brush and trees once cut down.

Just a follow up,, I'd like to be able to use the third function to run a skidsteer type post hole digger. small or low flow one of course, would this run into issues that I'm reading about concerning continuous operation of the valve?

Thanks.

I bought a Branson 3520H a couple weeks ago and I plan on installing a third function valve kit to run a grapple. I've not decided on the kit to buy but trying to understand how they are connected, I'm still a little unclear. They all connect to the Power Beyond port but then the general instructions are to run the T port to the return line/tank reservoir. I'm reading between the lines and assuming that if there is already a hose plugged into the PB port on the main loader valve running to the rear PTO, the third function valve kit is simply placed in series.

Original: Main Loader Valve PB-> Rear PTO

Modification: Main Loader Valve PB->third function valve kit P port-> valvekit T port-> original rear PTO line.

Is this correct or am I totally off base in my understanding?

BTW - for some background, I've purchased a 5 acre lot with about 1.5 acres of trees and brush that I want to clear off. The immediate need is to help load the logs that I've already cut down on to a portable sawmill but long term just helping to clear the brush and trees once cut down.

Just a follow up,, I'd like to be able to use the third function to run a skidsteer type post hole digger. small or low flow one of course, would this run into issues that I'm reading about concerning continuous operation of the valve?

Thanks.

Last edited: