California

Super Star Member

- Joined

- Jan 22, 2004

- Messages

- 14,697

- Location

- An hour north of San Francisco

- Tractor

- Yanmar YM240 Yanmar YM186D

Your readings match what I found on my YM240 and posted here.

www.tractorbynet.com

www.tractorbynet.com

As CalG said, a diesel is most efficient at the hottest it can run without damaging anything.

Seems to me Yanmar's ultra simple design concept for the 240's intended that light as nothing more than a boilover warning.

How simple are these? There's not even a thermostat. Regen? Didn't exist 50 years ago. Fuel gauge? Nope. The three warning lights and the tach cover the essentials. The operator manual even allows running without a battery. A simpler machine for simpler times.

Edit - added:

Oil & Fuel - Low oil pressure? No, bad sender!

I sometimes see questions here about what should temperature and oil pressure gauges show, and what causes the oil light to flicker. Maybe this longwinded narrative will answer some of these questions. I have owned my YM240 several years now with no issues at all, after an initial month...

As CalG said, a diesel is most efficient at the hottest it can run without damaging anything.

Seems to me Yanmar's ultra simple design concept for the 240's intended that light as nothing more than a boilover warning.

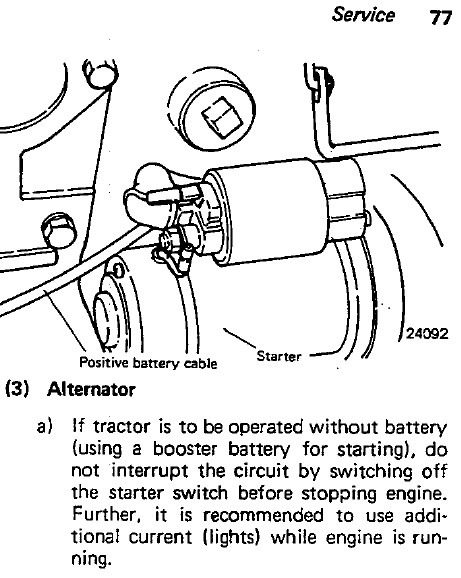

How simple are these? There's not even a thermostat. Regen? Didn't exist 50 years ago. Fuel gauge? Nope. The three warning lights and the tach cover the essentials. The operator manual even allows running without a battery. A simpler machine for simpler times.

Edit - added:

Last edited: