toukow

Silver Member

I'm hoping you guys can straighten me out. Can you tell me how I'm misapplying the documents at the links? I have attached excerpts from the Miller data (all white documents) at the links, as well as additional Victor tip data (documents with green) . My goal is simply to have the maximum range of tips on hand for cutting, without exceeding the bottle size flow limit.

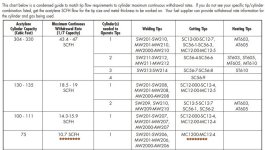

I found the maximum allowable flow rate in the first Miller document, which is simply applying the 1/7 rule for acetylene flow based on tank size. I have 75 cubic foot tank, so 10.7 SCFH is the limit. I know the new standards are now based on 1/10 of rated capacity for intermittent use. This also shows the tip range for this tank size to be 12-00/12-4.

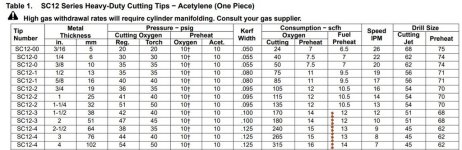

I found the flow rates for the Miller tips shown above, in particular the 12-3 & 12-4 tips, in the second excerpt. My confusion is that when I look at this tip specification flow rates for the 12-3 and 12-4 tips, it shows a flow rate which exceeds the maximum flow rate for a 75-cu ft tank.

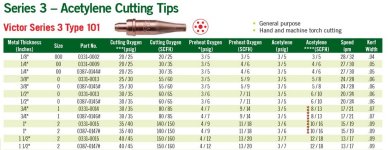

I have also attached excerpts for the Victor tips including the heating tips. In examining data from Victor, it seemed like a number #1 cutting tip made the most sense, given the #2 tip starts out with its flow equal to the maximum flow rate for my tank. My LWS is saying I can use the #2, but they did not really research the details when replying.

Thanks for your time, Toukow

https://www.millerwelds.com/-/media...xy-fuel/fuelgascylinderrequirements.pdf?la=en

https://equiptoweld.millerwelds.com...ding_Brazing_HeatingTip_FlowPressure_Data.pdf

View attachment 639459View attachment 639460View attachment 639461View attachment 639462

I found the maximum allowable flow rate in the first Miller document, which is simply applying the 1/7 rule for acetylene flow based on tank size. I have 75 cubic foot tank, so 10.7 SCFH is the limit. I know the new standards are now based on 1/10 of rated capacity for intermittent use. This also shows the tip range for this tank size to be 12-00/12-4.

I found the flow rates for the Miller tips shown above, in particular the 12-3 & 12-4 tips, in the second excerpt. My confusion is that when I look at this tip specification flow rates for the 12-3 and 12-4 tips, it shows a flow rate which exceeds the maximum flow rate for a 75-cu ft tank.

I have also attached excerpts for the Victor tips including the heating tips. In examining data from Victor, it seemed like a number #1 cutting tip made the most sense, given the #2 tip starts out with its flow equal to the maximum flow rate for my tank. My LWS is saying I can use the #2, but they did not really research the details when replying.

- What am I missing in interpreting the Miller data? Are these maximum values for flow rates for the respective Miller tips? Still don't see how a #4 will work.

- Does the #1 tip from the Victor data make sense to buy? Or can this bottle size support a #2 tip, given I appear to be missing something here?

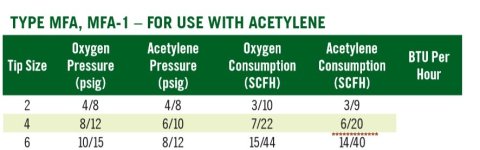

- I'm thinking of buying the MFA-1, Size 4 heating tip as well. I've read that fuel supply to heating tips can be an issue, but infer this tank can support such a flow rate.

Thanks for your time, Toukow

https://www.millerwelds.com/-/media...xy-fuel/fuelgascylinderrequirements.pdf?la=en

https://equiptoweld.millerwelds.com...ding_Brazing_HeatingTip_FlowPressure_Data.pdf

View attachment 639459View attachment 639460View attachment 639461View attachment 639462