Gord Baker

Gold Member

Just start in a new spot or use metal banding to attach whatever you are mounting.

This one did. The backside had to be smooth, so the column could slide up inside. All fixed, and wired, and working great.Tap extractors never work if you broke off the tap from binding, which it sounds like you did

My wife discourages the use of my paying someone else tool!!did break an easy out in a bolt once. I got it out by paying someone else...

I plan on doing this with a broken Irwin EZout stuck 40 years ago in a '59 Corvette 4 speed.I broke a 4-40 tap off in a small piece of aluminum a few years ago, and after some internet searching, I found a method using a concentrated alum solution. I mixed it up in a glass beaker and dropped the aluminum piece with the broken tap into it, and the next morning the tap was completely gone and the aluminum unharmed. Obviously though, that wouldn't work on a steel work piece.

Interesting. Let us know how that works, with pics...I plan on doing this with a broken Irwin EZout stuck 40 years ago in a '59 Corvette 4 speed.

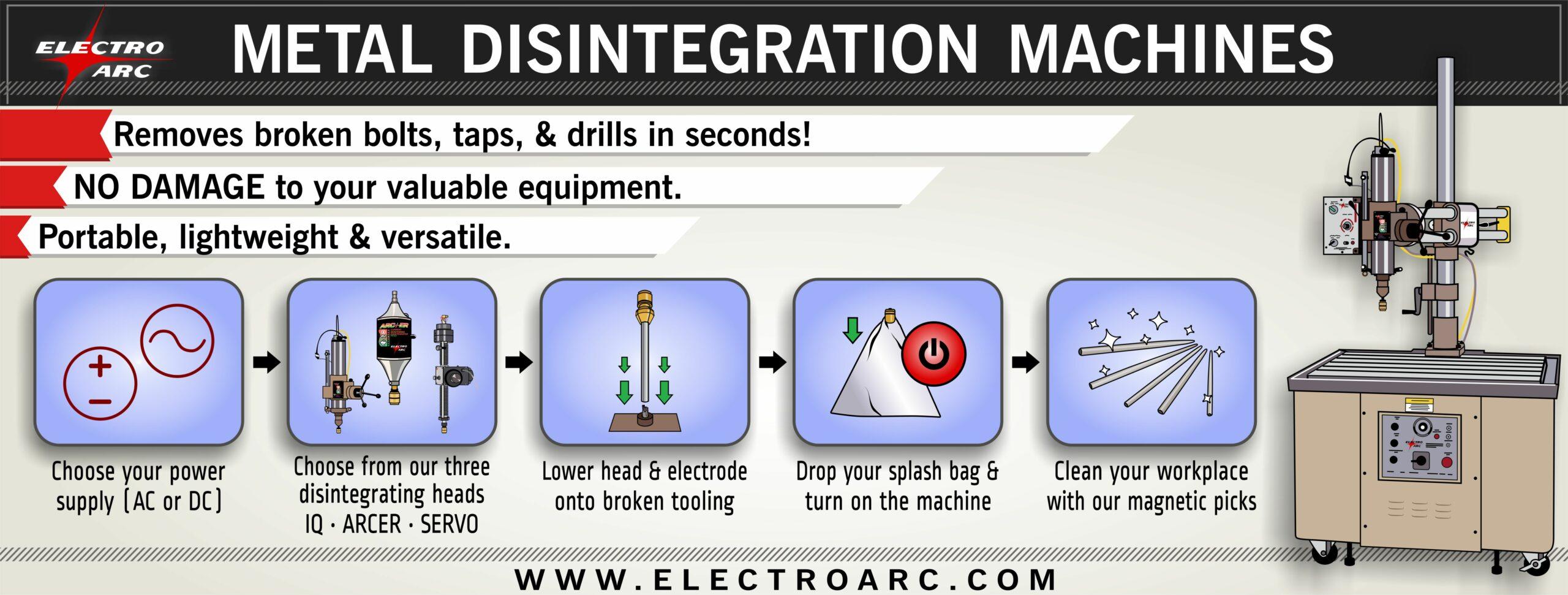

I have used those when I worked in a machine shop years ago. Get it centered over the broken tap or drill bit and let it do it's thing. Similar to an arc welder, but instead of adding metal it eats it away!Have you seen these?

The Metal Disintegration process for removing Broken Bolts

Not sure what metal disintegrator is for you? Here are 5 easy steps to choose the right metal disintegrator to remove broken boltselectroarc.com