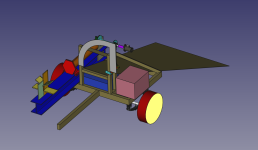

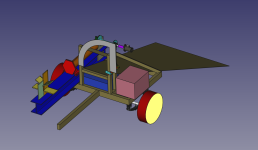

Yes it is great improvement not only in hours but in hard labor. A friend of mine saw my processor and ordered one for himself, but it is a slightly different style, as we doesnot want to use another machinery to lift the logs on the deck, while he is skidding 30ft long logs from the forest. This is the current design so far, and its a paid job so I have to have it ready in 2 weeks :confused2:, maybe thats a better approach you may be interested in, as it utilizes a winch to pull the logs.