Jay4200

Veteran Member

- Joined

- Nov 23, 2005

- Messages

- 2,028

- Location

- Hudson/Weare, NH

- Tractor

- L4200GST w/ LA680 & BX2200D w/ LA211

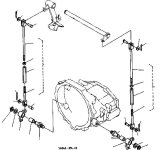

I tried to adjust the split brakes on my Kubota L4200 and found the adjustment turnbuckles seized. I removed the assemblys, soaked the threads with PB blaster, heated the turnbuckle with a torch, but all efforts failed to free the threads. The primary problem is that the assembly can only be secured at the ends of the bars, so there is anywhere from 6" to a foot of bar between the wrenches, so the bar was twisting before the threads could break free. I gave up and planned to replace the parts, but the two of them will cost ~$125 to replace, so I'd like to give it one more shot. Any suggestions on how to free these things up?

Thanks - JayC

Thanks - JayC