Thank youPolemidis,

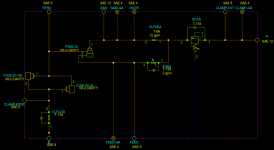

Connections to the "pressure modulating valve"

Top port: Connects to the Saw motor & feed oil in port.

Middle port: Connects to the CV08 150 check valve

bottom port: Connects to saw out.

I also have no idea on who makes the pressure modulating valve.

I believe that you will find one of manifolds to be rather expensive unless you can find a company that specializes in low volume manifold design and fabrication. The reason for this is that you are paying for the design time, machine set-up time in just one piece Vs 100's of pieces.

If saw cutting time is not important you can just set the feed rate so that on the largest toughest wood the saw does not stall and on smaller pieces you just wait longer.

good luck.

About the manifold, I learned how to use Sun hydraulics quick design and already submited it. I got a quote of $440 for the whole assembly. Manifold 5 cartridges and 5 ports. Not that expensive not too cheap. I guess if I want that automation I will have to pay. But look, an extra directional valve + a variable flow divider + a cast sequence valve + all the extra hoses to connect these parts will get close to that.

So, right now, I am redesigning the manifold, I will remove the check valves/ modulating valve, I will keep the 2 flow control valves (one for the saw motor at 12gpm and one for the feed at 1gpm, I will add the sequence valve inside the manifold, and also I will add 2 ports for pressure gauges. If it stays around that money I will go for it.

Thank you for your time!