oldboyscout

Silver Member

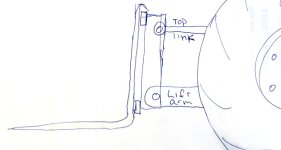

I'm about to build a pallet fork frame for my 3 point hitch. I'd like to keep the top link attachment low, so it is parallel to the lift arms, so the forks stay level when I lift.

Does that increase the forces on the 3 point linkage too much?

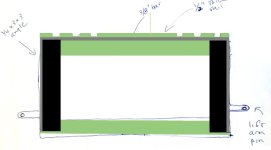

I'm also planning to simply weld the bottom and top bars to vertical 1/4" x3x3 angle, and run 3/8" x 2" bar at right angles to the top and bottom bars to stiffen them. I think this will be way stronger than anything I can lift with my B2620?

Does that increase the forces on the 3 point linkage too much?

I'm also planning to simply weld the bottom and top bars to vertical 1/4" x3x3 angle, and run 3/8" x 2" bar at right angles to the top and bottom bars to stiffen them. I think this will be way stronger than anything I can lift with my B2620?