v8dave

Platinum Member

That parts diagram looks remarkably like an old Flathead V8 Ford clutch assembly. Some differences, the clutch lever shaft, #26, is above the input shaft instead of below it. I'm going to make a rash assumption your transmission/clutch is similar to an old Ford.

There is a key part missing from your diagram, the bearing retainer. This is probably part of the transmission parts diagram. The transmission input shaft bearing retainer is more that just a bearing holder. It also has a snout on it which extends out from the transmission and covers the input shaft for a bit (1 to 2 inches). The throw out bearing, #24, and throwout holder, #23, slide on this part of the retainer.

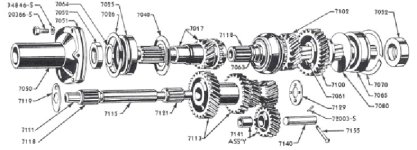

I've attached a diagram of a Ford transmission, the bearing cover is #7050. Notice the eylet on the flange (facing out).

If your transmission is anything like this, your bearing retainer is probably broken. I had a car once with the snout completely broken off, the throwout bearing was running on the input shaft--it almost worked.

Dry assemble the clutch on the input shaft. Is there a surface for #23 and #24 to run on? Is part #23 loose and running on the input shaft? If so the snout is broken off the retainer. And, since you can't find any eylets for the springs, they may be broken too.

Hopes this helps.

There is a key part missing from your diagram, the bearing retainer. This is probably part of the transmission parts diagram. The transmission input shaft bearing retainer is more that just a bearing holder. It also has a snout on it which extends out from the transmission and covers the input shaft for a bit (1 to 2 inches). The throw out bearing, #24, and throwout holder, #23, slide on this part of the retainer.

I've attached a diagram of a Ford transmission, the bearing cover is #7050. Notice the eylet on the flange (facing out).

If your transmission is anything like this, your bearing retainer is probably broken. I had a car once with the snout completely broken off, the throwout bearing was running on the input shaft--it almost worked.

Dry assemble the clutch on the input shaft. Is there a surface for #23 and #24 to run on? Is part #23 loose and running on the input shaft? If so the snout is broken off the retainer. And, since you can't find any eylets for the springs, they may be broken too.

Hopes this helps.