You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Homemade Backhoe for LS Tractor (XG3140)

- Thread starter polemidis

- Start date

/ Homemade Backhoe for LS Tractor (XG3140)

#31

texasranger556

Platinum Member

I wouldn't want to give up swing power, you will use it more than you think backfilling dirt, moving the pile over, or to reposition the rear of your tractor while digging or stuck.

Shoot for full 180 swing, you will appreciate the space savings in your shed or fitting on a trailer. Your proposed swing geometry looks like it will be very non-linear near the extremes and may even lock. I can measure the pivots on mine if you don't have access to a good example locally. It uses trunnion cylinders.

How much hydraulic flow does your tractor have? I would use the tractor hydraulics and avoid the extra pump, tank, filter, relief, etc. My tractor is rated at 8.3 GPM and runs the 8' hoe fairly well between half and two thirds throttle.

Shoot for full 180 swing, you will appreciate the space savings in your shed or fitting on a trailer. Your proposed swing geometry looks like it will be very non-linear near the extremes and may even lock. I can measure the pivots on mine if you don't have access to a good example locally. It uses trunnion cylinders.

How much hydraulic flow does your tractor have? I would use the tractor hydraulics and avoid the extra pump, tank, filter, relief, etc. My tractor is rated at 8.3 GPM and runs the 8' hoe fairly well between half and two thirds throttle.

I wouldn't want to give up swing power, you will use it more than you think backfilling dirt, moving the pile over, or to reposition the rear of your tractor while digging or stuck.

Shoot for full 180 swing, you will appreciate the space savings in your shed or fitting on a trailer. Your proposed swing geometry looks like it will be very non-linear near the extremes and may even lock. I can measure the pivots on mine if you don't have access to a good example locally. It uses trunnion cylinders.

How much hydraulic flow does your tractor have? I would use the tractor hydraulics and avoid the extra pump, tank, filter, relief, etc. My tractor is rated at 8.3 GPM and runs the 8' hoe fairly well between half and two thirds throttle.

No worries, I think the crossover relief valve is a good safety measure anyway. And Its easy to adjust. And it really does not add much to the cost.

About the tractor hydraulics. I was considering that. My LS is rated at 8.2gpm. The remote hydraulics would simplify everything. A lot. I mean I could have it 100% done ready for the plasma cutting in a week. But, I decided to go with the pto pump, for a few reasons:

a) Right now I do not have remotes. I have a 3rd function in front but its not rated for continuous operation. So I would have to pay $700 for the rear remotes. I have no doubt they would become handy at other projects though.

b) The pto pump will boost the flow to 14gpm at least. That extra flow will allow me to use wider cylinders, without sacrificing operating speed.

c) I have never welded with more than 180Amps. Nothing thicker than 1/4", not with proper penetration at least. I want a project to get experience with thicker still

Rational thinking I should go with the remotes as you say. But I want a challenge

texasranger556

Platinum Member

For a backhoe or anything with it's own valve you can just cut the line that connects the loader valve power beyond port and the three point input. Run the power beyond to your backhoe inlet, and the backhoe return to the tractor's sump. The three point gets no supply when the backhoe is installed...in my case I have to remove the 3 point arms anyway while the BH is installed.

Depending how your system is configured it could be as simple as making a couple hoses and adding some quick disconnects. For ultra cheap, if the line is steel you can cut it and braze JIC fittings straight to the steel lines. We have done that on several backhoe installs where I used to work, usually when the tractor used metric or ORFS fittings (pretty much anything beyond SAE/ORB, JIC, or pipe) that we couldn't find locally and customer was in a rush.

Depending how your system is configured it could be as simple as making a couple hoses and adding some quick disconnects. For ultra cheap, if the line is steel you can cut it and braze JIC fittings straight to the steel lines. We have done that on several backhoe installs where I used to work, usually when the tractor used metric or ORFS fittings (pretty much anything beyond SAE/ORB, JIC, or pipe) that we couldn't find locally and customer was in a rush.

For a backhoe or anything with it's own valve you can just cut the line that connects the loader valve power beyond port and the three point input. Run the power beyond to your backhoe inlet, and the backhoe return to the tractor's sump. The three point gets no supply when the backhoe is installed...in my case I have to remove the 3 point arms anyway while the BH is installed.

Depending how your system is configured it could be as simple as making a couple hoses and adding some quick disconnects. For ultra cheap, if the line is steel you can cut it and braze JIC fittings straight to the steel lines. We have done that on several backhoe installs where I used to work, usually when the tractor used metric or ORFS fittings (pretty much anything beyond SAE/ORB, JIC, or pipe) that we couldn't find locally and customer was in a rush.

Yeah, great input. I am completely comfortable with the hydraulics. (I have spent about $10,000 on surpluscenter already.... :confused3

Anyway, I have finished the tank, i will keep doing the external hydraulic system just for getting experience.

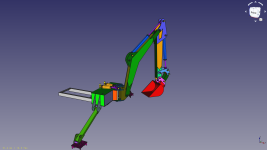

I made some more progress yesterday, I moved the swing cylinders towards the center and replaced them with smaller stroke ones.

Guys my progress is on the gitlab server. Usually I make progress twice per week, and I dont post all the details here to avoid overload you with too many useless details. I am mention it again, feel free to download the CAD files. If you are not familiar with Freecad, everything can be exported to .STEP files (kind of universal format)

It starts to take shape. I would like to review a few things (yes, the trunnion mount is one of them!!

)though. My main concern is that I have no much experience with heavy equipment and I do not know what is the industry standards.

)though. My main concern is that I have no much experience with heavy equipment and I do not know what is the industry standards.

Can you plz give your input on these things plz?

a) Pin size. Some basic calculations show that 1.25" diameter pins of mild steel are adequate. But I am not engineer so thats maybe completely off. does it sound good to you guys? What size pins do mini excavators have? If that size is at about the limits, maybe I will just buy harder steel, even though I would prefer to replace the pins and not the welded bushings. Mostl likely I will use 3" diameter cylinders on 2200-2500 psi

b) for bushings I am planning to buy 2" OD DOM tube, with 0.375" wall, and weld them, does that sounds good approach to you?

c) Unfortunately I cannot run the Finite Element Analysis. Maybe I have to simplify the model a lot and retry. But from your experience, what thickness should I go for the plates? 1/4" for the main shell, and 1/2" for the laminated ends (where the stresses are higher)?

Thank you guys!

p.s. I am mentioning it again, the model is on the link I gave you before, available to download. All my progress is there.

Can you plz give your input on these things plz?

a) Pin size. Some basic calculations show that 1.25" diameter pins of mild steel are adequate. But I am not engineer so thats maybe completely off. does it sound good to you guys? What size pins do mini excavators have? If that size is at about the limits, maybe I will just buy harder steel, even though I would prefer to replace the pins and not the welded bushings. Mostl likely I will use 3" diameter cylinders on 2200-2500 psi

b) for bushings I am planning to buy 2" OD DOM tube, with 0.375" wall, and weld them, does that sounds good approach to you?

c) Unfortunately I cannot run the Finite Element Analysis. Maybe I have to simplify the model a lot and retry. But from your experience, what thickness should I go for the plates? 1/4" for the main shell, and 1/2" for the laminated ends (where the stresses are higher)?

Thank you guys!

p.s. I am mentioning it again, the model is on the link I gave you before, available to download. All my progress is there.

TMGT

Elite Member

1.25 pins should be good for most of the pivots, I would step up to 1.5 for the main swing pivots and where the main boom and crowd arm mounts. Would recommend 1144 stressproof or at least 1045. For mine I used DOM with replaceable spring steel bushing or bronze bushing for the major pivots.

As for plating, mine has 1/4-1/2 depending on location.

As for plating, mine has 1/4-1/2 depending on location.

Thanks for the info!. Yeah for the king pin I have designed bigger pin, 2" i think.

But How these "replacing spring bushings" work? If the DOM will be 2"OD 1.25" ID, and the pin 1.25", how they fit? I like that idea to go with harder pins and put replaceable sleeve bushings, but I do not know how.

But How these "replacing spring bushings" work? If the DOM will be 2"OD 1.25" ID, and the pin 1.25", how they fit? I like that idea to go with harder pins and put replaceable sleeve bushings, but I do not know how.

TMGT

Elite Member

Bushings are 1/8" wall so just make the ID of the DOM .250" larger to compensate. Most of my sleeves are .250" wall DOM, .375 is a good wall thickness.

Do you have a lathe? You're going to need one to get good pin fitment either way using DOM.

Do you have a lathe? You're going to need one to get good pin fitment either way using DOM.

Thanks for the info!. Yeah for the king pin I have designed bigger pin, 2" i think.

But How these "replacing spring bushings" work? If the DOM will be 2"OD 1.25" ID, and the pin 1.25", how they fit? I like that idea to go with harder pins and put replaceable sleeve bushings, but I do not know how.

Plz let me know if I got it wrong:

Pin: 1144 steel 1.25" dia

Bushing: 1.25" ID 1.5" OD Something like this?

Housing: DOM Tubing 1.5" ID , with wall either 0.25" or .375"

And the DOM will be welded to the holes of the plates, which will be a little bigger as the plasma does not cut exactly precise.

If thats the case then grease has to come through the pin? Make 2 crossed holes?

Pin: 1144 steel 1.25" dia

Bushing: 1.25" ID 1.5" OD Something like this?

Housing: DOM Tubing 1.5" ID , with wall either 0.25" or .375"

And the DOM will be welded to the holes of the plates, which will be a little bigger as the plasma does not cut exactly precise.

If thats the case then grease has to come through the pin? Make 2 crossed holes?