drm

Silver Member

Eddie,

For what it is worth, and a bit late, I will once again butt in with my opinions.

What species of lumber is stocked in PT wood out your way? I would assume that the grade is #2 but you should ask. When I worked in Chicago, some time ago before wood went through the roof, we would use Douglas Fir Larch or Hem Fir. Here in PA we get SPF or Southern Pine. It is all regional. This is important since the design values can vary greatly depending on the species and grade.

Assuming you are going to use #2 Southern Pine spanning continuous over the middle support, I would use 2x10’s. The reason I would not use 2x12’s is that I have had a tough time finding straight 2x12’s that long and the 2x10’s are a little lighter to work with. I built a platform sticking out over a slope with continuous 2x10’s x 20’. I was able to erect all but the back columns, 6x6x10’ high posts, myself and it was plenty strong to support a prefab shed 12’x20’ fully loaded. I used 3 rows of double 2x10’ with 2x6’s (12’ long) spanning across. So I effectively only had 6 2x10’s over 12’ width. Not as much load but very stiff due to the continuous spans of the 2x10’s and 2x6’s.

Next is what spacing. 16” spacing would certainly work but 12” spacing will give a bit more rigidity. It is up to you.

Most importantly is the blocking between the 2x10’s. In a two span continuous beam like you will have the largest stresses will be at the center support and a bit past 1/3 points from the ends. The center support stresses will be from negative moments meaning that the top of the beam will be in tension and the bottom in compression. The bottom, since it is in compression, will want to buckle or kick out sideways. Therefore you must have full height blocking at the center support. You also need full height blocking at the midpoints and ends as a minimum. Providing them at third points instead of the midpoints would be better but probably overkill.

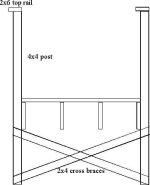

Next is the attachment of the railing. I would use the blocking at third points since I would use posts at the ends and third points and blocking behind the post attachment is imperative. Spanning a railing 5 feet seems too long to me.

I would go with 5/4x6 decking due to cupping and put them tight.

Good luck and I will try to keep up with you guys.

…Derek

For what it is worth, and a bit late, I will once again butt in with my opinions.

What species of lumber is stocked in PT wood out your way? I would assume that the grade is #2 but you should ask. When I worked in Chicago, some time ago before wood went through the roof, we would use Douglas Fir Larch or Hem Fir. Here in PA we get SPF or Southern Pine. It is all regional. This is important since the design values can vary greatly depending on the species and grade.

Assuming you are going to use #2 Southern Pine spanning continuous over the middle support, I would use 2x10’s. The reason I would not use 2x12’s is that I have had a tough time finding straight 2x12’s that long and the 2x10’s are a little lighter to work with. I built a platform sticking out over a slope with continuous 2x10’s x 20’. I was able to erect all but the back columns, 6x6x10’ high posts, myself and it was plenty strong to support a prefab shed 12’x20’ fully loaded. I used 3 rows of double 2x10’ with 2x6’s (12’ long) spanning across. So I effectively only had 6 2x10’s over 12’ width. Not as much load but very stiff due to the continuous spans of the 2x10’s and 2x6’s.

Next is what spacing. 16” spacing would certainly work but 12” spacing will give a bit more rigidity. It is up to you.

Most importantly is the blocking between the 2x10’s. In a two span continuous beam like you will have the largest stresses will be at the center support and a bit past 1/3 points from the ends. The center support stresses will be from negative moments meaning that the top of the beam will be in tension and the bottom in compression. The bottom, since it is in compression, will want to buckle or kick out sideways. Therefore you must have full height blocking at the center support. You also need full height blocking at the midpoints and ends as a minimum. Providing them at third points instead of the midpoints would be better but probably overkill.

Next is the attachment of the railing. I would use the blocking at third points since I would use posts at the ends and third points and blocking behind the post attachment is imperative. Spanning a railing 5 feet seems too long to me.

I would go with 5/4x6 decking due to cupping and put them tight.

Good luck and I will try to keep up with you guys.

…Derek