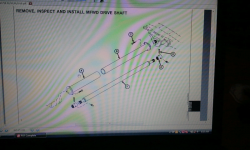

I looked at JDparts to compare your MFWD drive shaft to that of my 5210 and they look the same. The following is from the tech manual for my 5210, attached picture from JDparts

1. Remove cap screws (3).

2. Slide guards (1 and 2) together.

3. Remove spring pin (5).

4. Slide couplers (4) toward drive shaft (6) and remove drive shaft assembly.

5. Inspect parts for wear or damage. Check drive shaft for straightness. Replace parts as necessary.

6. Apply Moly High Temperature EP Grease to ID of couplers (4).

7. Install drive shaft assembly.

8. Install drive shaft guard cap screws (3). Tighten to specification.

Specification

Drive Shaft Guard Cap

Screws Torque ....................................................... 15 (11 lb-ft)

Having trouble finding this procedure in the technical manual. You recall what section you found it in? I am probably looking right at it!