aeblank

Veteran Member

I think this is what I'm going to do...........

I measured the travel on my SSQA. On mine, the bottom bolt that attaches to the spring/pin etc. travels "exactly" 4". It is a 12x1.25x25mm bolt, according the the parts diagram.

As such.....

8" travel 100lb force actuator from here: Linear Actuator IP66 | Progressive Automations for $149

Replace the bolt that is there with a longer bolt and a nut (mcmaster numbers 91180A731 ($7.48) and 91415A235 ($9.41)).

Probably some washers 98023A033 at $6.00 or locally by the pound.

Seems like this should be able to be cheaper, but some tubing 7767T53 @ $45.16 (or, for another $100 they will make me a custom length shaft). Maybe some black pipe or something? Needs to fit over the 1.1" shaft without "much" slop.

Cost: 149+7.48+9.41+6+45.16 = $217

Still need wiring, plugs, and switches.

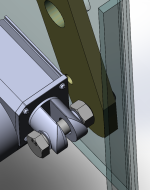

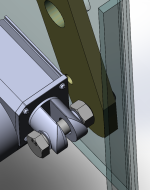

See mockup of one end mounting below:

Notes:

Thoughts?

EDIT: A chunk of 1" schedule 40 black pipe will work out real nice cause the O.D. is a bit less than my mcmaster number'd pipe above. Just need to drill/ream/flapper wheel the I.D. a little bigger to slip over the actuator's shaft. Likely easy enough. It's 1/2 the cost of the pipe listed above. Both prices from mcmaster. I think I need a 16" length, so this 18" piece for $8 is even better... LDR Industries 1 in. x 18 in. Black Steel Schedule 40 Cut Pipe-306 1X18 - The Home Depot

So the price would be more like $180.

I measured the travel on my SSQA. On mine, the bottom bolt that attaches to the spring/pin etc. travels "exactly" 4". It is a 12x1.25x25mm bolt, according the the parts diagram.

As such.....

8" travel 100lb force actuator from here: Linear Actuator IP66 | Progressive Automations for $149

Replace the bolt that is there with a longer bolt and a nut (mcmaster numbers 91180A731 ($7.48) and 91415A235 ($9.41)).

Probably some washers 98023A033 at $6.00 or locally by the pound.

Seems like this should be able to be cheaper, but some tubing 7767T53 @ $45.16 (or, for another $100 they will make me a custom length shaft). Maybe some black pipe or something? Needs to fit over the 1.1" shaft without "much" slop.

Cost: 149+7.48+9.41+6+45.16 = $217

Still need wiring, plugs, and switches.

See mockup of one end mounting below:

Notes:

There isn't a quick-removal if the thing screws up. That was one goal I had originally, to be pinned on for easy removal.

- With the 8" actuator, I am maximizing my leverage. As such, I'm pretty comfortable using the lower force (and faster!) longer travel actuator. I just didn't like where the 6" travel actuator needed to mount.

- I don't have to drill holes, tap, or anything.

- I DO have to lengthen the threaded section of the new bolt, I think. A tap is $6.

- I am using the intended mounting (including fastener size) of the actuator

Thoughts?

EDIT: A chunk of 1" schedule 40 black pipe will work out real nice cause the O.D. is a bit less than my mcmaster number'd pipe above. Just need to drill/ream/flapper wheel the I.D. a little bigger to slip over the actuator's shaft. Likely easy enough. It's 1/2 the cost of the pipe listed above. Both prices from mcmaster. I think I need a 16" length, so this 18" piece for $8 is even better... LDR Industries 1 in. x 18 in. Black Steel Schedule 40 Cut Pipe-306 1X18 - The Home Depot

So the price would be more like $180.

Last edited: