Creamer

Elite Member

This is simple. Since you are talking about ledger plates i am assuming that you have the older, thicker mower style guards and not the newer haybine type. these are more difficult to adjust than the newer ones but it can be done.

Assuming your cutter bar and sickle bar are straight:

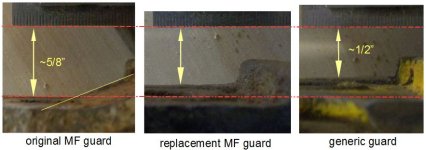

1st - it sounds like you have different styles of guards mixed on the cutter bar. Try to get the same styles grouped so you do not have a lot of transitions.

2nd - Install the wear plates behind the sickle in the most retracted position possible. Then check for contact of the wearplate with the sickle in the fore/aft direction and adjust so that they are all just touching the sickle bar. You should replace any wearplates that are worn more than halfway through. You can push this limit some but you do not want a wearplate to give out while you are cutting.

3rd - check guard to bottom of section clearance (assuming you have decent sections and that they are not bent). Adjust the guards up or down - any guard including the cast ones because I do not know of any that are not - using a hammer and hitting near the tip of the guard. You can also use a pipe over the end of the guard. I can never remember breaking a guard this way unless it was previously cracked. The sickle should lie flat on the ledger plates - if not you have guard style issue but most are interchangeable.

4th - adjust the holddowns via tapping with a hammer so that they are just touching the top of the sickle sections.

5th - verify your sickle moves easily. I am not familiar with the MF machine but you can turn a pulley or take the drive loose and move the sickle by hand. You should not have to pound on it.

6th - start the tractor and run the sickle and watch and listen - watching for for aft movement and any jerkiness and listening for rattle. shut the tractor off and check for any catch points or heat build-up. You should not be able to see the sickle catching and anywhere and it may be a little warm but certainly touchable. If it is hot you have it constrained to tightly and would not have passed #5

7th - lubricate the sickle with used oil at all the wear plates and hold downs. I prefer using a Dawn Dishwashing detergent type squeeze bottle which gives me control and keep my hands away from the sickle. Now when you run it you should hear much less noise.

You should be ready to go.

Basically you have ti give the sickle a straight path to run in and constrain it so it does not bounce around. Then make sure you have not overconstrained it and make sure you maintain the scissor like action between the section and the ledger plate. Personally I have never seen ledger plates wear out. i have seen them rusted beyond any degree of sharpness and need to be replaced and other types of damage but it has had to have lots of use to have been worn out. Last year I bought a sickle bar mower from the 60s that had been used on a dairy farm for 30 years and then not run since but stored inside and the ledger plates are in fine shape.

Good luck!

Assuming your cutter bar and sickle bar are straight:

1st - it sounds like you have different styles of guards mixed on the cutter bar. Try to get the same styles grouped so you do not have a lot of transitions.

2nd - Install the wear plates behind the sickle in the most retracted position possible. Then check for contact of the wearplate with the sickle in the fore/aft direction and adjust so that they are all just touching the sickle bar. You should replace any wearplates that are worn more than halfway through. You can push this limit some but you do not want a wearplate to give out while you are cutting.

3rd - check guard to bottom of section clearance (assuming you have decent sections and that they are not bent). Adjust the guards up or down - any guard including the cast ones because I do not know of any that are not - using a hammer and hitting near the tip of the guard. You can also use a pipe over the end of the guard. I can never remember breaking a guard this way unless it was previously cracked. The sickle should lie flat on the ledger plates - if not you have guard style issue but most are interchangeable.

4th - adjust the holddowns via tapping with a hammer so that they are just touching the top of the sickle sections.

5th - verify your sickle moves easily. I am not familiar with the MF machine but you can turn a pulley or take the drive loose and move the sickle by hand. You should not have to pound on it.

6th - start the tractor and run the sickle and watch and listen - watching for for aft movement and any jerkiness and listening for rattle. shut the tractor off and check for any catch points or heat build-up. You should not be able to see the sickle catching and anywhere and it may be a little warm but certainly touchable. If it is hot you have it constrained to tightly and would not have passed #5

7th - lubricate the sickle with used oil at all the wear plates and hold downs. I prefer using a Dawn Dishwashing detergent type squeeze bottle which gives me control and keep my hands away from the sickle. Now when you run it you should hear much less noise.

You should be ready to go.

Basically you have ti give the sickle a straight path to run in and constrain it so it does not bounce around. Then make sure you have not overconstrained it and make sure you maintain the scissor like action between the section and the ledger plate. Personally I have never seen ledger plates wear out. i have seen them rusted beyond any degree of sharpness and need to be replaced and other types of damage but it has had to have lots of use to have been worn out. Last year I bought a sickle bar mower from the 60s that had been used on a dairy farm for 30 years and then not run since but stored inside and the ledger plates are in fine shape.

Good luck!