hi all:

new update.

I managed to remember the camera and took a of of pics and will post them on photobucket with links in this thread later. (have to work tonight.)

short version

I got the OLD pump apart, new seals and still when tight would not rotate. SO put in new pump bearings and pump drive shaft. every thing works so far no foaming, got to fully re-assemble seat tuck in wires & hoses add tie wraps back onto couplers ect.

OK anyhow long version

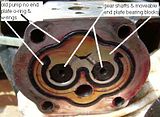

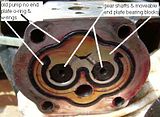

after I got pump & spare kit from Jerry down in TX @ Affordable Tractor I went at the OLD pump first, put in the kit only to have the pump lock up when tight, it would spin freely when no seal pressure was on the pump of course it leaks like a sieve like that but when tight it wouldn't rotate or let motor turn over even. closer inspection & taking pump 100% apart found that the gear drive and the gear drive end bearing/floating plates were slightly scored and so was one bearing surface inside the pump gear shaft bearing surface. these were all cleaned up to near polished surface at work. looked great & performed well. but only when the pump was left LOOSE. what I found was that the new pump kit was pushing the end plates IN and compressing them onto the PUMP GEARS which would lock them in place. no fix for this yeat but what I did was to use the new seals and tighten the pump down together and added 2 3/8" long bolts to the empty 2 holes and simply bolted it all tight to let the seals get compressed hopefully relieving the seal compression problem when if I ever need the pump...

since I was putting in the NEW pump I put in a NEW pump drive shaft as well. when pulling this apart I needed direction and got a little help from CHIP over at Bolton but he was only able to confirm that it came out the back face side were the pump mounts & couldn't remember what all had to come out.

SO I went after it, the PUMP is held onto a moderately heavy plate using 2 of the 4 pump bolts the other 2 bolts simply hold the pump parts all together. This PLATE is held onto the Engine by 2 bolts that goes in from the front of the engine gear train cover all the way through and into this moderately heavy plate.. the top bolt holds the Alternator Bracket and the Bottom bolt is bottom center of the cam/injection pump/hyd pump drive gear cover. then there is a 1.5 x ~14 MM thread pitch bolt which looks like a Oil Drain Bolt. I removed that bolt which then lets you gain access to the back side of the Hyd Pump Drive Shaft. It has to be Pushed Out probably using that threaded hole if you can find the proper bolt or all thread rod. It can only be about 5" long but would be nice to find one longer if need be and cut it off so that it would make a great little tool. I ended up using a punch and pry bar as the radiator is too close to swing a hammer. but only AFTER that heavy plate is removed as that retains the shaft & bearings & gear that drives the pump.

I ended up popping the outer race off one of the bearings as there is no good way to remove them off the shaft, the gear comes off easily after the bearings are out of way. also there are 2 different types of shafts. Jerry sent me both shafts as I didn't know WHICH one I had but after seeing both and what I had you can tell them apart while still in the tractor but you need to get in there to really see and have hyd pump removed too. the SHORT shaft is flat on front and the longer one has an extra step cut into the front face.

anyhow every thing was re-assembled and the 2 bolt pump intake flange was left loose and the hyd tank was filled all way up, I took the hyd vent plug put that in and put 5~10 lbs of pressure of air into the pump vent pushing hyd fluid down the pump suction line and pushing the air out of the lose connection pre-filling the pump suction line and pump to prevent more air sucking and or more pump problems... NOTE: I held open end of the air gauge/hose onto the vent tube, not tight inside was <u> <b>low pressure</u> </b> so as to not blow anything up. all worked out well and I tightened the pump suction line 2 bolt flange & fired it up. all was well very little to no foaming (entrapped air in lines & cylinders only) while cycling FEL & 3 pt lift to remove air out of those. so far all seems WELL

will add pics later.

edit in pics click pic to view full size from photo bucket ~40 k each down sized

Mark M