LD1

Epic Contributor

It is not a static situation with a load on the cyl such as a couple of hundred lbs.

Describe how that is not a static situation?

200#, 800#, 1500#, does not matter how much weight is in the bucket. IF the weight isnt moving it is a static load.

Just like the dead weight of the loader and bucket itself.

IF you think a 300# empty loader bucket is a static load, how is that any different than a set of 100# pallet forks instead of the bucket, and 200# on them.

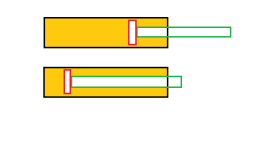

But regardless, we are getting off topic. The only thing adding weight does is increase the pressure in the cylinder. And increasing the pressure inside the cylinder also increases the pressure in the fittings, hoses, and valve. So adding weight will increase leaking where ever it may be happening.