OP

boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,824

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

revisting tires / tracks for the STB

came across the following site. gives a lot of pictures of tires to tracked vehicles.

Special Offroad Vehicles

some pictures that i found on above site...

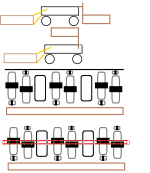

it almost looks like both set of tracks could have a 360 joint placed on them. (front and back tracks)

nice long bus on 2 sets of tracks... awe!! i could see a STB! but instead of a bus some engines and implements folded up on top!

hhmmsss it might be able to have all sets of tires have a 360 joint on them. but man large diameter tires... and the height just to reach top of the flat bed....

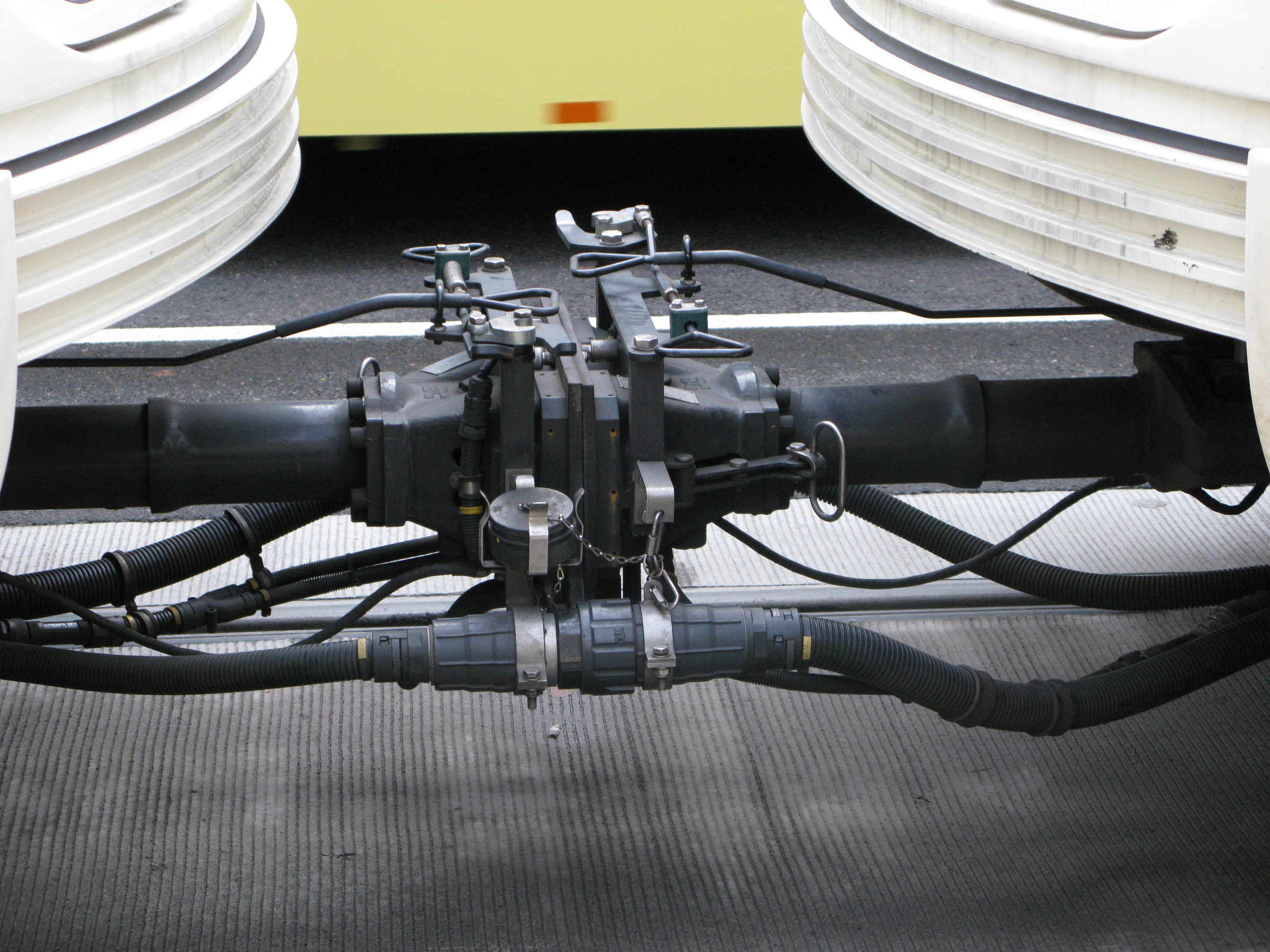

gave idea of possible what the linkage might look like between 2 sections of the STB. but not sure.. looks way to short of distance hhmmss..

========================

got to thinking about amusement park rides more specifically teacups

google -> amusement park rides teacups

below image is from Tea Cup Rides 3D Highlights

and then planetary gears

google -> planetary gears

Planetary Gear Set - YouTube

Ravigneaux compound planetary gear set - YouTube

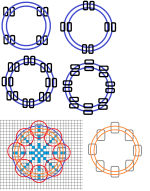

then started thinking back at different track and/or wheel combinations...

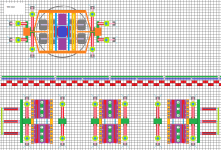

to the last diagram...

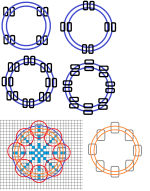

perhaps a large "circle" frame work that operated under principles of a planetary gear setup. to both allow the wheels to turn 360 degrees. but also to run a drive axle down to each wheel.

when looking back at previous diagram/s

it would still be possible to get 8 tires and possibly reduce the dead man circle

the problems is "row crop" spacing. if you wanted to run STB in field without driving over the crops... and then individual turning of wheels (360 joint rotation), different RPMs for different wheels and different torque for different wheels..

the vertical drill bit tiller... :confused2: aka the "class 3 TORNADO maker"

aka the "class 3 TORNADO maker"

EDIT:

hurricanes = water

tornadoes = wind

volcanoes = earth

calling it the "class 3 volcano maker" fits better as dirt erupts out the center.

came across the following site. gives a lot of pictures of tires to tracked vehicles.

Special Offroad Vehicles

some pictures that i found on above site...

it almost looks like both set of tracks could have a 360 joint placed on them. (front and back tracks)

nice long bus on 2 sets of tracks... awe!! i could see a STB! but instead of a bus some engines and implements folded up on top!

hhmmsss it might be able to have all sets of tires have a 360 joint on them. but man large diameter tires... and the height just to reach top of the flat bed....

gave idea of possible what the linkage might look like between 2 sections of the STB. but not sure.. looks way to short of distance hhmmss..

========================

got to thinking about amusement park rides more specifically teacups

google -> amusement park rides teacups

below image is from Tea Cup Rides 3D Highlights

and then planetary gears

google -> planetary gears

Planetary Gear Set - YouTube

Ravigneaux compound planetary gear set - YouTube

then started thinking back at different track and/or wheel combinations...

to the last diagram...

perhaps a large "circle" frame work that operated under principles of a planetary gear setup. to both allow the wheels to turn 360 degrees. but also to run a drive axle down to each wheel.

when looking back at previous diagram/s

it would still be possible to get 8 tires and possibly reduce the dead man circle

the problems is "row crop" spacing. if you wanted to run STB in field without driving over the crops... and then individual turning of wheels (360 joint rotation), different RPMs for different wheels and different torque for different wheels..

the vertical drill bit tiller... :confused2:

EDIT:

hurricanes = water

tornadoes = wind

volcanoes = earth

calling it the "class 3 volcano maker" fits better as dirt erupts out the center.

Last edited: