TO_Bud

Silver Member

Well not me specifically, it was a family thing. My son recently purchased some lakefront property in northern Michigan, real pretty 1 acre wooded lot on an equally pretty sandy bottomed lake. The lot is virgin wooded with an assortment or hardwoods and quite a few poplars and pines. Also throughout the property is years and years of fallen timber and stumps mostly rotted and half submerged in the soil. Anyway while he was pushing over, boxblading and clearing with the grapple he ran over ran over a 6" branch that rotated up under the tractor and caught the diverter block just perfectly. Before he realized it the block was pushed upward to the point that a steel hydraulic line broke. Actually the the line didn't break the fitting sheared off flush with the diverter block. He didn't have proper tools with him at the time so he left the tractor as it was and came home for the week. He felt the steel line was bent so he ordered (overnighted) a new fitting and line (going to the joystick) from the local NH Dealer. Oh did I forget to mention, I haven't been told of the mishap at this point. He felt he could repair it himself, no harm no foul right? I think you know where I'm going with this. He drives back up the following weekend and begins the repair. I finally sniff out a problem when he calls me to ask what is the proper hydraulic fluid for the tractor. He spends several hours laying in the dirt getting the broken fitting out only to find the dealer ordered the wrong steel line. Luckily there is a Kubota Dealer a few miles away who is able to make up short hydraulic hose with the correct fittings for him. He and I are communicating with texts all this time (bad cell signal) and I'm getting frustrated. If anyone has worked on the TC's joystick plumbing you know how difficult it is to get to the flare nuts in the back. He finally texts me that it is back together and running, all hydraulics are working but the Hydro pedals are not going down far enough so the tractor is only creeping along.

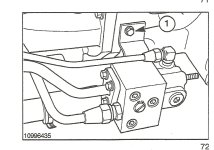

I had him load it up and bring it home so I can see what the problem is. Turns out the log pushed the diverter block up to the point the steel lines were now interfering with the pedal movement. The lines were restricting the pedals to about 1/3 of their normal travel.. Not only that but all the remaining steel lines were tweaked to the point that if they were removed from the block they would not line back up when the blocks bracket was straightened and the block was back where it should be. I would have been replacing several steel lines, not an attractive option. I decided to leave them all attached and try to get the block back down where it belonged. If one or more lines broke I wouldn't be any worse off anyway. Well getting the block back down where it belonged was easier said than done. I finally was able to use a pipe wrench with a cheater to get everything realigned, all the while praying I didn't damage the diverter block. I made small little corrections until it was clear of the pedals. Everything appears OK, some pipe wrench teeth marks on the diverter housing but nothing cracked and I don't have any leaks, at least now after running it for 1/2 hour or so. That's the end of my long story, keep your fingers crossed for me, the tractors going back up for more abuse this weekend. This is a pretty tough machine.

I had him load it up and bring it home so I can see what the problem is. Turns out the log pushed the diverter block up to the point the steel lines were now interfering with the pedal movement. The lines were restricting the pedals to about 1/3 of their normal travel.. Not only that but all the remaining steel lines were tweaked to the point that if they were removed from the block they would not line back up when the blocks bracket was straightened and the block was back where it should be. I would have been replacing several steel lines, not an attractive option. I decided to leave them all attached and try to get the block back down where it belonged. If one or more lines broke I wouldn't be any worse off anyway. Well getting the block back down where it belonged was easier said than done. I finally was able to use a pipe wrench with a cheater to get everything realigned, all the while praying I didn't damage the diverter block. I made small little corrections until it was clear of the pedals. Everything appears OK, some pipe wrench teeth marks on the diverter housing but nothing cracked and I don't have any leaks, at least now after running it for 1/2 hour or so. That's the end of my long story, keep your fingers crossed for me, the tractors going back up for more abuse this weekend. This is a pretty tough machine.