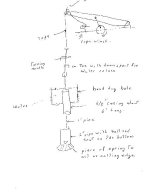

go look at the picture,

the cable/rope is threaded through a series of pulleys. and the "walking beam" the (teeter toter type arm), it purpose is to pull the cable up and then drop it,

by making, a crank (powered and geared down from the engine), the crank (with a roller) on the crank to reduce friction and wear, when the cable is down the walking beam is in the up position with the tail of it down, the crank comes around and catches under the beam and lifts it up on the tail end, moving the pulley end of it down pulling the cable up, as crank nears the top of the rotation, (in the drawing) it slips off and let the cable drop,

(the main draw back of this design is one will need to create a stop to limit the drop or watch it close so the crank can always get under the beam,

on the second, ( see video aobut 50 seconds into it),

the difference there is a swinging arm that is attached, to the crank and to the beam,( or directly to the pully) and the fixed section of the crank catches the arm at the top of the stoke (rotation of the crank), and then pulls/rotates it to the down position, and when it over centers at the bottom It allows the cable/rope to drop, or free fall, swinging up very fast, and as the slower crank comes back around catches the arm and pulls it down, and repeats the cycle.

(the idea is to pull the cable down and drop fast it so the bit can do it work of digging the hole), by letting the bit pulverize the dirt or soil in the hole,

(very similar to using a bar in a post hole to bust up the dirt, rock or what ever, in the bottom of the hole so it can be removed), after pulverizing the dirt a "bucket" with a one way vale is used to clear the mud out of the hole and once it is done you re enter with the bit and pound again when you have more mud than you can effectively pound through you bucket it out, and repeat, until you have the depth you want,

so having two winches one for the drilling bits and one for the bailer, is many times considered a plus,

the winch on the bit will need to have the ability to be let up little by little so the bit can lower and so the max length of drop can be obtained,

depending on the depth, and how large your unit is, one may just want to pull it by hand, under 100 feet it may be easiest, than using winches,

or a lawn tractor or car could be used, to do it but one would need to watch carefully so one does not pull it up to far and pull over your mast,

one could use a capstan type winch as well,

people have done this by just pulling on the rope and dropping it,

Wellspring Africa's Hand Powered Percussion Drill

a few more links of intrest

http://www.consallen.com/How-to-drill_Cable-Percussion.pdf

http://www.consallen.com/forager/forager-200.htm

links in page for more info on bits and buckes and other tools that make the unit work,

there are U tube and some other sites geared for the thrid world on how to make your own tools,

some former discusions,

http://www.tractorbynet.com/forums/build-yourself/144891-well-drilling-power-take-off.html

http://www.tractorbynet.com/forums/build-yourself/159341-cable-drilling-winch.html