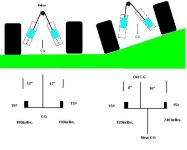

The diagram I created, was with a 15 degree incline. So for the upper side tube to go horizontal, the tractor would have be on an incline of 75 degrees.

Edit: That's not quite right, because the tube has a built in angle of ?? 15 degrees. So, maybe the tractor would have to be on a 60 degree incline (which you shouldn't be on in the first place).

As a test example, if the weights were 15 pounds and the lower 12 inch arm decreased by 4 inches, the moment would be 120 inch/pounds, while at the same time the upper arm would increase from 12 by 4 inches, the moment would be 240 inch/pounds. (which doesn't factor in the angle) With the tractor level, there would be 180 inch pounds on both sides, at balance.