Zola

New member

Hi, new member here, longtime lurker.

We would like to build ourselves a nice pole barn house (I love the look of barns, and the gambrel roof gives us space for bedrooms)

I'm at the research stage, I have a couple of books, I've looked at a bunch of the posts here about pole barns, and I've checked out some of the stuff on the web.

We're planning a size of 24' x 32', and this is where my question comes in.

In the book, it shows the main girts as being an unbroken length of lumber. I highly doubt I can get lumber that's 2 x 12 x 32, so obviously I'll have to splice.

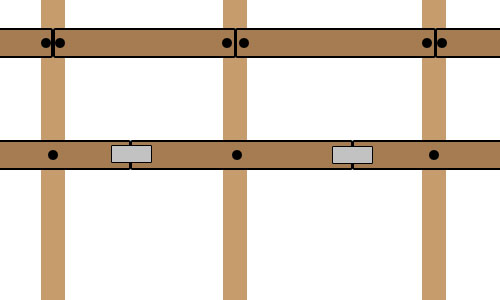

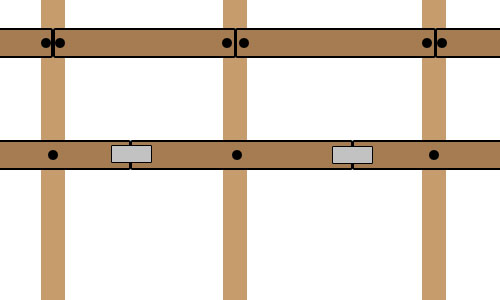

I made a quick diagram of the two possible methods of splicing that come to mind. The first butts the ends together on a pole and each is held by a carriage bolt.

The second splices the boards somewhere in-between the poles, using metal connectors.

Which method is better? We're planning on using class 7 utility poles spaced at 8' intervals (20' poles on the outside and 25' on a line in the center).

Strength is very important because we are sometimes subject to high winds/microbursts from thunderstorms, small tornadoes, heavy snow loads, and even a chance of a minor earthquake. I'd like the building to have the best chance of surviving any one of those if at all possible.

We would like to build ourselves a nice pole barn house (I love the look of barns, and the gambrel roof gives us space for bedrooms)

I'm at the research stage, I have a couple of books, I've looked at a bunch of the posts here about pole barns, and I've checked out some of the stuff on the web.

We're planning a size of 24' x 32', and this is where my question comes in.

In the book, it shows the main girts as being an unbroken length of lumber. I highly doubt I can get lumber that's 2 x 12 x 32, so obviously I'll have to splice.

I made a quick diagram of the two possible methods of splicing that come to mind. The first butts the ends together on a pole and each is held by a carriage bolt.

The second splices the boards somewhere in-between the poles, using metal connectors.

Which method is better? We're planning on using class 7 utility poles spaced at 8' intervals (20' poles on the outside and 25' on a line in the center).

Strength is very important because we are sometimes subject to high winds/microbursts from thunderstorms, small tornadoes, heavy snow loads, and even a chance of a minor earthquake. I'd like the building to have the best chance of surviving any one of those if at all possible.