genusCastor

Silver Member

A couple months ago I bought a used Yanmar-Cub Cadet SC2400, has a belly mower and end loader.

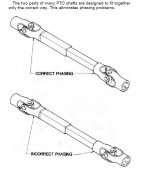

I've had the mower deck off a couple times now, and I'm pretty well certain there's only one orientation of the PTO that allows the shaft to slip on. I see one groove on the deck (female coupler) that is wider than the rest, and a groove between two splines on the tractor (male end) that seems to be filled in making a spline that's wider than the rest, and apparently those two (wide groove and wide spline) must be aligned. Any other orientation and the shaft will not slide all the way on.

I discovered this anomaly the first time I hooked the deck back up. Yesterday, even though I understood(?) the specific orientation, it was still difficult to get it lined up. Can't see that well up underneath there. Prolly took me close to an hr to get that thing back on. Seemed like it anyway, I dint time it.

thing back on. Seemed like it anyway, I dint time it.

Does this sound familiar? I did some innerweb research but can't find anything about this. I'm thinking I could dremel whatever it is between the two splines on the tractor shaft and then it would go on in any orientation. I can't imagine any functional reason it would be designed to be specifically oriented, it can't be blade timing ... can it?

- djb

I've had the mower deck off a couple times now, and I'm pretty well certain there's only one orientation of the PTO that allows the shaft to slip on. I see one groove on the deck (female coupler) that is wider than the rest, and a groove between two splines on the tractor (male end) that seems to be filled in making a spline that's wider than the rest, and apparently those two (wide groove and wide spline) must be aligned. Any other orientation and the shaft will not slide all the way on.

I discovered this anomaly the first time I hooked the deck back up. Yesterday, even though I understood(?) the specific orientation, it was still difficult to get it lined up. Can't see that well up underneath there. Prolly took me close to an hr to get that

Does this sound familiar? I did some innerweb research but can't find anything about this. I'm thinking I could dremel whatever it is between the two splines on the tractor shaft and then it would go on in any orientation. I can't imagine any functional reason it would be designed to be specifically oriented, it can't be blade timing ... can it?

- djb