Maine_Polack

Gold Member

I am in need of a rake to mount on three point. With what I have in mind is using it to gather brush, and to loosen soil, if I want.

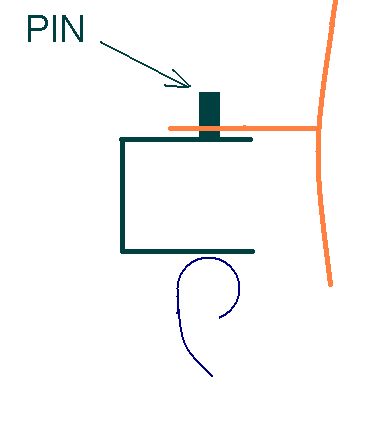

I have this heavy duty, 8" rear blade. Instead of building a whole new rig to mount a rake on, I would like to use this blade.

Con't...

I have this heavy duty, 8" rear blade. Instead of building a whole new rig to mount a rake on, I would like to use this blade.

Con't...